COMPANY NEWS

Croda’s PCM operations shift to Spain

As part of its acquisition of most of Croda International’s performance technologies and industrial chemicals businesses, agribusiness giant Cargill took possession of Croda’s research, development and manufacturing site in Gouda, Netherlands.

But Croda held onto its PCM business. That work will continue at a Croda facility in Spain. Martin Butters, technical and business development manager for Croda’s new Industrial Specialties unit, answered questions about the transition via email:

Q: What is your role at Croda?

A: “I have been with Croda for seven years in a business development/technical role, primarily involved in supporting customers and our global sales teams, and supporting the lab team at Croda, with regard to the CrodaTherm PCM product range. All in all, I have worked with PCMs in technical and business roles for nearly 20 years.

“My role has expanded in terms of responsibilities; however, there is no change concerning CrodaTherm PCMs. My colleagues and I will continue to support our customers as we have done before.”

Q: Croda CEO Steve Foots said the sale of the PTIC businesses accelerates the company’s transition “to being a pure-play consumer care and life sciences company.” How does retaining the PCM business align with that focus?

A: “Elements of the PTIC (Performance Technologies & Industrial Chemicals) business that were essential to the Consumer Care and Life Sciences sectors have been retained within Croda under a new business unit called Industrial Specialties. In addition to CrodaTherm PCMs, the unit offers speciality ingredients used for textiles, emulsion formulations, polymeric dispersions and more.

“The business will continue as before. We have an established product offering suitable for low, moderate and higher temperature applications, the latter in particular well suited to thermal energy storage applications, which we will continue to explore and develop with our customers. We will also continue to focus on opportunities for our range of CrodaTherm ME microencapsulated PCM products for textiles and potentially other applications such as construction.”

Q: Will Croda continue to produce its full range of PCMs?

A: “Yes, this is the idea. Production of nearly all CrodaTherm products will be carried out at our facility in Spain, near Barcelona (we produce two other grades in Singapore). The Spain site is also where our PCM technical lab is now located and led by my colleague Dr. Jon Vilasau. We are in the process of setting up production in Spain of those products that were previously produced at the Gouda site in the Netherlands, which is no longer owned by Croda.”

Q: How long has Croda’s site in Spain been producing PCMs?

A: “The site is highly specialised in producing the type of chemistry from bio-based raw materials that is used for CrodaTherm PCMs and has been doing this for many years. Production of CrodaTherm products in Spain started early 2020.”

Q: How many people are employed at the technical lab in Spain?

A: “The structure is still to be finalised, but we have a number of people who have been working with CrodaTherm PCM’s plus a wider team based at the site.”

Q: Are any new products on the horizon?

A: “We will expand our microencapsulated PCM range with new grades to be introduced later this year/early 2023. Regarding standard CrodaTherm PCMs, we already have an extensive product range and several developmental products ‘on the shelf’ we can look to introduce in the future if merited by the business case.”

Q: Will Croda continue its membership in the RAL Quality Association PCM?

A: “Yes. Jon will be the primary Croda representative and I will also attend some meetings.”

Q: Has your contact information changed?

A: “Some new options are available which should make it even easier to contact us.”

• Email inquiries: crodaindustrialspecialties@croda.com

• CrodaTherm webpage, inquiry form and live chat: crodaindustrialspecialties.com/en-gb/functions/phase-change-materials

• Through the regional sales offices listed on the Industrial Specialties website, or your local sales representative.

PARTNERSHIPS

Phase Change Solutions teams up with GAF

Phase Change Solutions Inc. of Asheboro, N.C., has announced a strategic partnership with GAF to develop and commercialize advanced materials for thermal management. The partnership includes integration of BioPCM, PCS’ core technology, with GAF products in the building and construction markets.

GAF was the lead investor in Phase Change Solutions’ most recent series C funding round, which also included Emerald Technology Ventures, Circulate Capital, Third Prime and GC Ventures America. The funding amount was not disclosed.

Govi Rao joined Phase Change Solutions as CEO in early 2020. He answered a few questions by email:

Q: You’ve led PCS through a period of significant change: new products, new investors, new partnerships and new hires. Describe what your goals for the company were at the outset, and the progress you’ve made toward achieving them.

A: “PCS’ goals have always been to be a leading advanced materials provider and we are continuing the same path. We have focused our efforts on this specific goal and are making the pivots necessary to stay on track.”

Q: How many employees did PCS have in April 2020, and how many are employed now?

A: “We have about 10% fewer employees now than we did in 2020.”

Q: Can you provide a breakdown of employees by job category?

A: “Research, development and manufacturing: 85%. All other: 15%.”

Q: Will existing PCS products (such as ENRG Blanket) be added to the GAF product line? If so, when? Are PCS and GAF working together to develop new products, such as PCM-enhanced gypsum board?

A: “We are working on our strategy and will have more info later this year.”

Q: What are your goals for the company in 2023?

A: “Keep all employees safe. Focus on building out the BioPCM platform. Growth in targeted segments – cold chain and logistics, datacom/telecom, building energy efficiency. Educate the ecosystem on BioPCM and advanced materials.”

IN BRIEF

• In the market for 900 tons of hexadecane? PCM manufacturer InnoCap of Hangzhou, China, is looking to liquidate its inventory of Inno C16 at a loss to clear warehouse space for another product. The material has a melting point of 18˚ Celsius and a heat storage capacity of 220 joules per gram. Contact Jolie Lei Chen, the company’s president and founder, for details.

• As the United Kingdom braces for heating and electricity prices expected to rise by 80 percent this winter, Sunamp Ltd. is pitching its Thermino heat batteries as a way for households to control costs. “Swapping out an old [hot water] cylinder for an electrically charged Thermino 210e in a family home will immediately save up to 940 kWh of electricity each year thanks to lower heat losses, saving as much as £485, and more if prices continue to rise,” said CEO Andrew Bissell.

• As the United Kingdom braces for heating and electricity prices expected to rise by 80 percent this winter, Sunamp Ltd. is pitching its Thermino heat batteries as a way for households to control costs. “Swapping out an old [hot water] cylinder for an electrically charged Thermino 210e in a family home will immediately save up to 940 kWh of electricity each year thanks to lower heat losses, saving as much as £485, and more if prices continue to rise,” said CEO Andrew Bissell.

• How did Sunamp get its start? How do its heat batteries work? CEO Bissell explains it all succinctly in a video podcast with DevicePilot CEO Pilgrim Beart.

• Kyoto Group of Norway has signed a letter of intent with corrugated cardboard manufacturer Glomma Papp to enter into a supply agreement for Kyoto’s thermal energy storage system, the Heatcube. Energy Storage News reports that a system could be commissioned as early as next summer.

• Researchers at the Massachusetts Institute of Technology have found a way to boil water faster. A specially treated surface causes bubbles to form at specific separate points rather than spreading out in a film across the surface. Improving the efficiency of systems that heat and evaporate water, such as power plants, could significantly reduce energy use.

• Global Energy Interconnection Research Institute Europe of Berlin has an opening for a thermal energy storage research engineer. The engineer will play a leading role in the research and development of energy storage systems. Requirements include a master’s degree in engineering thermal physics, process engineering, chemical engineering or comparable qualification.

• Matt Ferrell, “a lifelong tech enthusiast” with more than 1 million YouTube subscribers, takes a look at phase change materials and their energy-saving potential in homes.

• The agenda has been posted for Sustainable Places 2022, to be held as a hybrid event in Nice, France, Sept. 6-9. Conference workshops include “Renewable Heating and Cooling for Buildings and Industry,” “Measuring Building Performance and Operational Rating,” “Tools and Technologies for Hybrid Thermal and Electric Grids towards Sector Coupling” and “Innovative Financing for Energy Efficiency Investments.”

• Advanced Cooling Technologies Inc. of Lancaster, Pennsylvania, has developed a thermal management system designed to keep biodigesters at the optimal temperature for biogas production. Biodigesters convert organic waste into methane-rich biogas and nutrient-dense fertilizer. “The digester design developed by ACT,” writes Elizabeth Seber of Power magazine, “uses inexpensive PCMs as a thermal buffer between the hot water tubes and the temperature-sensitive digestate. Placing PCM between the hot water and digestate allows the PCM to prevent excessive temperature shocks to the system.”

PATENTS

Dual PCM liquid suspension

U.S. patent application 20220267657 (applicant Packaging Technology Group LLC, Fall River, Mass.):

“A dual PCM liquid suspension is formed by blending a liquid phase change material having a first phase change temperature, a microencapsulated phase change material having a second phase change temperature, a thickening agent, and a surfactant and heating the blended materials for a period of time to form a permanent liquid suspension. PCM liquid suspension behaves as a viscous liquid and may be filled in PCM bottles with conventional liquid filling equipment. The PCM liquid suspension may be preconditioned and stored at a single temperature.”

PCM core thermoplastic shell filament

U.S. patent application 20220243998 (applicant Alliance for Sustainable Energy LLC, Golden, Colorado, and TCPoly Inc., Atlanta, Georgia):

“The present disclosure relates to encapsulation of a phase change material (PCM) enabled by extrusion of a thermoplastic polymer shell and a PCM core, which can be additively manufactured to form a variety of designs for use in a variety of settings, including for use as thermal energy storage devices in building heating ventilation and air conditioning (HVAC) systems. The thermoplastic polymer shell surrounding a PCM core may be used as a filament in three-dimensional (3D) printing or may be extruded during the additive manufacturing process.”

Container for storing and serving frozen confectionery items

U.S. patent application 20220242568 (applicant Conopco Inc., dba Unilever, Englewood Cliffs, N.J.):

“A thermally insulated container for storing and serving frozen confectionery items, wherein the container is preferably arranged to be removably mounted within a service cart, such as an inflight service cart. … [The thermally insulated container] comprises dry ice positioned in contact with the reservoir of phase change material, preferably on top of the first reservoir of phase change material.”

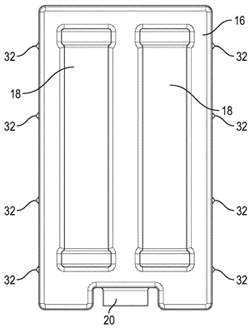

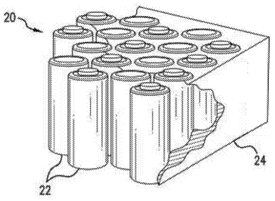

Fast charging batteries at low temperatures with battery pack preheating

U.S. patent application 20220271352 (applicant All Cell Technologies LLC., Broadview, Illinois):

“A method and apparatus for charging a battery pack including a plurality of electrochemical cells distributed within a thermal management composite matrix, including a phase change material. The method operates upon determining that a battery pack temperature and/or voltage measurement is below a predetermined minimum threshold. The pack temperature and/or the voltage measurement is raised to the predetermined minimum threshold, such as by applying a low current rate, and then the charging rate is increased upon reaching the predetermined minimum threshold. The increased charging rate is further selected based upon a thermal state of charge of the thermal management composite matrix.”

More U.S. patent applications:

Smoke-free cigarette (Olig AG, Lucerne, Switzerland) | Temperature-controlled storage container (B Medical Systems S.a.r.l., Hosingen, Luxembourg) | PCM-integrated insulation (University of North Texas, Dallas) | Energy storage device (TVS Motor Co. Ltd., Chennai, India) | Apparatus and composition for cooling items with a contained PCM (Hercules Manufacturing Co., Henderson, Kentucky) | Mixture of PCM waxes as an element for accumulating latent heat in electric machines (Eldor Corp., Orsenigo, Italy) | Packaging for pharmaceutical products (REP IP AG, Zung, Switzerland) | Cooling cosmetic compositions (Biogenics Inc., Daejeon, South Korea)

RESEARCH ROUNDUP

From Journal of Polymer Research:

From Energy and Buildings:

From Energy Nexus:

• Phase Change Materials for Battery Thermal Management of Electric and Hybrid Vehicles: A Review

From Applied Thermal Engineering:

• Thermal Energy Storage based on Cold Phase Change Materials: Charge Phase Assessment

From Journal of Energy Storage:

• Cladding phase change materials in freezing and chilling zones of household refrigerator to improve thermal performance and environmental benefits

• Effect of surfactants on encapsulation of hexadecane phase change material in calcium carbonate shell for thermal energy storage

• Energy, economic and environmental impact analysis of phase change materials for cold chain transportation in Malaysia

• Numerical evaluation of thermal energy storage rate in planar and cylindrical phase change material composites

• Experimental study on simultaneous use of phase change material and reflector to enhance the performance of photovoltaic modules

• A review on thermophysical properties and thermal stability of sugar alcohols as phase change materials

From Applied Nanoscience:

From Renewable Energy:

• An experimental investigation on performance of microencapsulated phase change material slurry in ground heat exchanger

• Efficient heating of buildings by passive solar energy utilizing an innovative dynamic building envelope incorporating phase change material

From Journal of Renewable and Sustainable Energy:

• Review on bio-based shape-stable phase change materials for thermal energy storage and utilization

From Royal Society of Chemistry:

From Research Square:

From Journal of Food Engineering:

• Cold thermal energy storage for milk chilling: A numerical and experimental study

From Journal of Molecular Liquids:

From Construction and Building Materials:

From Innovative Food Science & Emerging Technologies:

From Energy Reports:

• Short recent summary review on evolving phase change material encapsulation techniques for building applications

• Shape-stabilized orange peel/myristic acid phase change materials for efficient thermal energy storage application

From Solar Energy Materials and Solar Cells:

From 2nd International Conference on Materials Chemistry and Environmental Engineering:

• The research progress in the application of phase change materials for building energy conservation

From Thermochimica Acta:

From Building and Environment:

From Food Hydrocolloids:

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,700 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,700 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Bradley Scott, process engineer at Encapsys LLC, Appleton, Wisconsin; R A Kumaran, chief engineer, Arctic LNG GBS project, Siberia, Russia; and Paresh Gujarati, assistant professor at C.G. Patel Institute of Technology, Ahmedabad, India.

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

Axiotherm GmbH | Croda International Plc. | ISU Chemical Co. Ltd. | RuhrTech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | S.Lab Asia Inc. | Sunamp Ltd. | va-Q-tec AG