SOLAR ENERGY

Yotta Energy battery stores PV power right on the roof

Phase change material comes in many forms and is suited to a wide range of cooling and heating applications, everything from coffee tumblers and thermal batteries to cooling vests and shipping containers for temperature-sensitive pharmaceuticals. In many applications, the weight of PCM can be a design challenge.

In some applications, though, the weight is perfect fit. Yotta Energy of Austin, Texas, has found that sweet spot with SolarLeaf, a 1-kWh lithium-iron phosphate battery that sits below rooftop solar panels while also acting as ballast.

In some applications, though, the weight is perfect fit. Yotta Energy of Austin, Texas, has found that sweet spot with SolarLeaf, a 1-kWh lithium-iron phosphate battery that sits below rooftop solar panels while also acting as ballast.

Designing a solar-plus-storage solution for the roof of a commercial building is a complex process. Buildings vary in size and surroundings. Most businesses don’t want a battery the size of a shipping container in their parking lot. By pairing batteries with rooftop solar panels, Yotta has devised a modular system that can cut 20 to 30 percent of the planning, permitting and engineering costs involved in a centrally located battery with equivalent storage capacity.

In an interview with Phase Change Matters, Yotta CEO Omeed Badkoobeh answered questions about the SolarLeaf:

Q: How did you become familiar with the PCM technology as a possible solution for thermal management of lithium-ion batteries?

A: “It was a little bit thanks to my co-founder [Vikram Iyengar, Yotta’s chief technology officer]. We had come up with the concept of panel-level storage, right? And we said, wow, if you could put batteries into this format, the way micro inverters have been popularized, you would simplify the heck out of integration of energy storage. And we said, well, there’s no battery chemistry except for some really high-grade military-scale lab cells that can exist in these different extreme temperatures.

“And so in order for this product to be reality, we had to come up with a unique thermal management system, and that’s kind of where we stumbled upon phase change material and moved towards a phase change heat exchanger. It’s a completely solid state design. There are no moving parts.”

Q: Each solar leaf has a capacity of 1 kWh, weighs about 50 pounds and is the size of a suitcase. So, by weight, how much PCM is there in one of those units?

Q: Each solar leaf has a capacity of 1 kWh, weighs about 50 pounds and is the size of a suitcase. So, by weight, how much PCM is there in one of those units?

A: “Even if I wanted to share the answer, I don’t think I know the exact off the top of my head. But it doesn’t take a whole lot of the PCM, right? Our system is not just the PCM, it’s this ceramic insulator that we use to create this buffer between the daytime high and the nighttime low.”

Q: What type of PCM is used?

A: “It’s a biobased PCM with a peak melting point of about 38 degrees C. In the future, we will probably have different mixtures for the different climate zones. We went with 38 because it was the most universal, applied to basically 90 percent of all climates.”

Q: In what material is the PCM encapsulated?

A: “Aluminum.”

Q: What are the key features of the heat exchange unit?

A: “It’s simple. It’s foolproof. There’s no point for it to fail once it’s assembled correctly. In creating panel-level storage, you have to create a thermal system that can mirror the life potential of the solar cells. The expectation in our industry is 20 years, right? Liquid cooling won’t last that long because you still have fans and pumps, and HVAC won’t last that long. And of course doing nothing, which is what most battery companies are doing today. They’re just doing nothing. And if you look at their warranties, there’s, you know, it’s stripped of any capacity retention.”

Q: How much concrete ballast is typically used to secure a rooftop solar panel?

A: “It depends on wind loads. But typically it’s one to two concrete blocks per solar module, especially around the edges of the array. The blocks weigh about 32 to 36 pounds. So our SolarLeaf battery replaces two ballast blocks. And what’s interesting is that installers hate dealing with ballast blocks, and ballast blocks disintegrate. These are 20-year systems, and when ballast blocks disintegrate, they become sand and they actually damage the roof.”

Q: What rooftop temperature extremes is the SolarLeaf designed for?

A: “We designed for the worst case scenario in a market like Phoenix, Arizona. And we took the hottest day on record and multiplied to four days in a row. And we work backwards from the design there on the thermal technology. It varies because wind flow is a big factor. But we’ve designed all the way up to about 160 degrees Fahrenheit. On the lower temperature range, that’s the only technology that’s active, a heat system that’s controlled by the battery management board. It only uses about 5 watts on average of power to run the heating. We’ve tested this system all the way down to, like, negative 40 F.”

A: “We designed for the worst case scenario in a market like Phoenix, Arizona. And we took the hottest day on record and multiplied to four days in a row. And we work backwards from the design there on the thermal technology. It varies because wind flow is a big factor. But we’ve designed all the way up to about 160 degrees Fahrenheit. On the lower temperature range, that’s the only technology that’s active, a heat system that’s controlled by the battery management board. It only uses about 5 watts on average of power to run the heating. We’ve tested this system all the way down to, like, negative 40 F.”

Q: Yotta is working on incorporating the system into building and fire codes. Can you give an update on that process?

A: “We use a very safe battery chemistry. It’s called LFP, lithium-iron phosphate. It’s heavier and that’s where the weight of the product generally comes from, but it is extremely safe. The worst scenario that happens with a thermal runaway from an LFP is that it off-gases. It can catch fire but only at extremely high temperatures. We know this because we’re literally undergoing UL9540A testing, which is proving the product by purposely trying to catch it on fire to see how it propagates. We are very confident that once we have these results that we were proving that our format of energy storage and our key technology make the deployment of energy storage extremely safe.

“One of the big dangers with lithium-based batteries or any energy source having so much potential energy in one specific location is that then when you do have a thermal runaway it can cascade very quickly. And that’s nearly impossible with our product because it’s a nominal 1-kWh battery pack, spaced about 3 feet apart at center. And just so happens that NFPA 855 regulations specifically asked for that kind of spacing.

“It’s like the early days of any new technology. Some jurisdictions won’t have any issues and some will be more strict. Our goal is that once we get past that first set of projects the follow-ons will be really simple because AHJs [authorities having jurisdiction] will be like, ‘OK, I know this technology, I’ve seen all the certifications, great. It’s just the same thing on a different rooftop.’ ”

Q: How are commercialization efforts going?

A: “We’re ramping up production now. We are a bit behind schedule because we’ve been hit pretty hard with the component shortages, competing against all these mega companies who are also having these problems. Otherwise we would have more projects in the ground, live.”

Q: How many employees do you have, and where is the product manufactured?

A: “It’s growing. We have about 27 employees now. And we’re going to get to about 42 by the end of this year. Today the SolarLeaf is manufactured in Asia with our partner, Flex. But we are aggressively looking at bringing manufacturing to the U.S. at some point.”

PATENTS

Composite window with thermal shock resistance

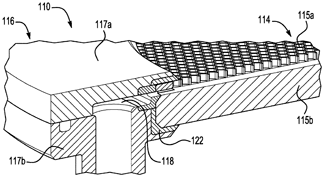

U.S. patent application 20220033053 (applicant Raytheon Co., Waltham, Mass.):

“A window installation includes a phase-change filler material [122] sealing an outer edge of the window, and coupling the window to a frame around the window. The filler material in a solid state rigidly holds the window in place. When the filler material is in a liquid state it allows the window to float in its coupling to the frame. There may be supports within the rigid material that contact the window, but allow the window to expand or contract by sliding along the supports. The installation may be useful in situations where the window is subjected to thermal shocks, or other sorts of heating. The installation may be used for a sensor window, and may be part of a hypersonic vehicle.”

Thermal storage system with coupled tanks

U.S. patent application 20220042718 (applicant UT-Battelle LLC, Oak Ridge, Tenn.):

“Methods and apparatus are disclosed for high-efficiency thermal storage with a fluid-filled ‘battery’ tank positioned within a fluid-filled ‘reservoir’ tank. Fluid loops couple the tanks to a heat pump and a building. The heat pump can charge the battery tank or deliver thermal energy (cold or heat) to a building, using the reservoir tank or ambient air as a thermal energy source. The battery tank can discharge energy to the building jointly with the heat pump or, at periods of peak electricity usage, with the heat pump switched off. Operating modes allow significant savings in electricity usage and mitigate the “duck curve.” Low duty cycle usage of the reservoir enables efficient underground thermal storage with less digging than conventional geothermal technologies. Additional efficiency is achieved with phase change materials installed inside a tank or in a tank wall, providing temperature regulation.”

Heat resistant portable storage

U.S. patent application 20220033168 (inventors Maria Grenier, Deltona, Fla., and

Elsa Vela, Mission, Texas), Location):

“A heat resistant portable storage device is provided. The heat resistant portable storage unit may include an outer shell, a thermal liner, and a facing material. The heat resistant fabric that may comprise the thermal liner of the portable storage device may be comprised of non-woven fabric, may be resistant to moisture, and may be coated with one or more heat resistant coatings. … An aspect of this disclosure advantageously provides for a thermal liner that may include a phase change material to help maintain temperature stability inside the portable storage unit.”

“A heat resistant portable storage device is provided. The heat resistant portable storage unit may include an outer shell, a thermal liner, and a facing material. The heat resistant fabric that may comprise the thermal liner of the portable storage device may be comprised of non-woven fabric, may be resistant to moisture, and may be coated with one or more heat resistant coatings. … An aspect of this disclosure advantageously provides for a thermal liner that may include a phase change material to help maintain temperature stability inside the portable storage unit.”

Heating elements for thermally-driven phase transition implantable micropump

U.S. patent application 20220047804 (applicant Cochlear Ltd., Macquarie University, Australia):

“An apparatus includes an enclosure containing a hermetically sealed region, the enclosure configured to be implanted on or within a recipient. The apparatus further includes circuitry within the hermetically sealed region and configured to generate signals. The apparatus further includes at least one heating element configured to receive the signals and to generate heat in response to the signals. The apparatus further includes at least one flow control element outside the hermetically sealed region and configured to respond to the heat by controlling a flow of liquid through at least one cannula to controllably administer the liquid internally to the recipient. … [At] least one flow control element comprises a phase-change material configured to respond to the heat by changing from a first phase having a size with a first magnitude to a second phase having a size with a second magnitude different from the first magnitude.”

More U.S. patent applications:

TES system with nucleation cooling (Rocky Research, Boulder City, Nev.) | Ductwork system for modulating conditioned air (Robert Alderman, Poteet, Texas) | Dual function domestic hot water preheater and integrated space heater (Radiator Labs Inc., New York, N.Y. | Battery assembly and electronic device (Beijing Xiaomi Mobile Software Co., Beijing, China) | Methods and systems for thermal energy storage and their use in buildings applications (Alliance for Sustainable Energy LLC, Golden, Colo.) | Kitchen-connected indoor stationary solar cooking device (Indian Oil Corp. Ltd., Mumbai, India) | A method of producing capsules (Agency for Science, Technology and Research, Singapore)

IN BRIEF

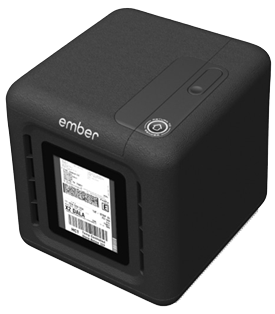

• Ember Technologies Inc. and Cardinal Health are forming a cold chain partnership based on “the world’s first self-refrigerated, cloud-based shipping box.” The reusable Ember Cube is designed to keep temperature-sensitive cargo within a desired temperature range without power for up to 72 hours. The Cube features cloud-based temperature reporting and GPS tracking. Phase change material is used to keep payloads in the desired temperature range during shipment. If temperatures exceed that range, the box can be plugged in, via a USB C port, to power an on-board refrigeration system, cooling the payload and recharging the PCM. Cardinal Health plans to launch a customer pilot for the product later this year.

• Ember Technologies Inc. and Cardinal Health are forming a cold chain partnership based on “the world’s first self-refrigerated, cloud-based shipping box.” The reusable Ember Cube is designed to keep temperature-sensitive cargo within a desired temperature range without power for up to 72 hours. The Cube features cloud-based temperature reporting and GPS tracking. Phase change material is used to keep payloads in the desired temperature range during shipment. If temperatures exceed that range, the box can be plugged in, via a USB C port, to power an on-board refrigeration system, cooling the payload and recharging the PCM. Cardinal Health plans to launch a customer pilot for the product later this year.

• Sunamp Ltd. of East Lothian, Scotland, has been awarded £149,893 for a feasibility study to further develop the storage duration of its thermal batteries. The award is part of the U.K. government’s £1 billion Net Zero Innovation Portfolio. “This funding will accelerate how we can further enhance thermal storage duration to meet the challenges of electrification of heat,” said Sunamp CEO Andrew Bissell. “Heat pumps with thermal storage have a much lower cost of operation than gas or night storage heaters. We are proposing a model where householders can directly own a share of a wind farm and can choose competitive tariffs which can be supplemented with solar PV to power their home heating system.”

• Pluss Advanced Technologies of Gurugram, India, received recognition from the Global Innovation & Technology Alliance on GITA’s 10th Foundation Day. In a LinkedIn post, the company wrote: “Pluss was announced as the winner under the small industry category for the application of PCMs in freezers and coolers that has enabled a reduction of 25% in over 1 lakh freezers and coolers operating since 2013 saving over 45Gwh.”

• Product manager Raj Bhaladhare and business development manager Deepika Singhal have joined Pluss Advanced Technologies’ new products initiative team. Harshit Kanodia has joined Pluss as general manager of operations.

• Registration is open for free webinar, “Test Methods for Thermal Energy Storage Materials,” presented by Adam Harris and Arya Hakimian of C-Therm Technologies Ltd., Canada. The webinar will be held Thursday, March 3.

• The International Energy Research Center, Ireland, has an opening for a full-time researcher specializing in building energy modeling.

• The Birmingham Energy Institute, Birmingham, England, has an opening for a research associate in thermal energy storage engineering for domestic heating applications.

• Alexium International Group Ltd., makers of Eclipsys, an adaptive cooling technology, is partnering with Premier Body Armor of Gastonia, N.C., to commercialize the technology. Alexium, based in Greer, S.C., and Perth, Australia, makes flame-retardant and PCM-enhanced fabric treatments.

• Christopher Day, director of marketing and innovation at Sonoco ThermoSafe, Arlington Heights, Ill., is undergoing a variety of treatments for a rare blood disorder. He has been receiving weekly exchanges of temperature-sensitive plasma as part of the regimen. “It’s hard to say if it’s the fatigue or vulnerability of having so many different drugs and processes going on for so long,” he wrote in a LinkedIn post, “but when I looked down and saw the plasma being unloaded from one of our ThermoSafe systems, I was overwhelmed. It was like my ThermoSafe family had made a container just for me. I thought of all the people in our various departments and facilities that had a hand in getting this to me. I could visualize a chain of people I know handing it from one to the next until it arrived. Not many people get to experience such a remarkable connection to the products they make, and I wanted to share my deep gratitude to my colleagues at ThermoSafe. You sustain me in so many ways.”

RESEARCH ROUNDUP

From Materials Today:

• A review on phase change materials (PCMs) for thermal energy storage implementations

From EnergyChem:

From Solar Energy Materials and Solar Cells:

From International Journal of Automotive Technology:

From Journal of Thermal Analysis and Calorimetry:

From Heat Transfer:

• Fabrication of portable solar thermal bank for indoor cooking

From Journal of Energy Storage:

• A deep supercooling eutectic phase change material for low-temperature battery thermal management

• A review on carbon-based phase change materials for thermal energy storage

From Clean Energy:

• Investigation of phase-change materials for interior temperature regulation in public transport

From Applied Sciences:

From Journal of Building Engineering:

From Thermal Science and Engineering Progress:

From Energy and Buildings:

From Renewable and Sustainable Energy Reviews:

From Energy:

From Energy Reports:

From International Journal of Thermophysics:

• Single and Multi-phase Change Materials Used in Cooling Systems

From Heat Transfer Engineering:

• Experimental Investigation of the Melting Process of Immiscible Binary Phase Change Materials

From Solar Energy:

From International Journal of Energy and Environmental Engineering:

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,700 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,700 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Nastaran (Nelly) Barhemmati, thermal energy scientist, Viking Cold Solutions, Houston, Texas; Abrar Ahmad, structural engineer, Khyber Pakhtunkhwa, Pakistan; Semra Ergen, professor of physics, Gaziosmanpasa University, Tokat, Turkey; Amit Bavejaa, head of government relations at B Medical Systems, New Delhi, India; Ludger Josef Fischer, program manager at NTN Innovation Booster Energy Lab, Zurich, Switzerland; Togan Tülüoğlu, project engineer at Arçelik Global, Istanbul, Turkey; Philipp Roos, thermal systems engineer at Cowa Thermal Solutions AG, Zurich; Dinesh Patki, general manager at Softbox Systems India Ltd., Maharashtra, India; and S. Christopher, mechanical engineer, Chennai, India.

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at info@pcm-ral.de.

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at info@pcm-ral.de.

Axiotherm GmbH | Croda Europe Ltd. | ISU Chemical Co. Ltd. | RuhrTech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | Sunamp Ltd. | va-Q-tec AG

MEMBER SPOTLIGHT: ISU CHEMICAL CO. LTD. | Seoul, South Korea

ISU Chemical specializes in pure organic raw material for phase change material, with an applied temperature range of minus 60 degrees Celsius to 18 degrees Celsius. ISU’s paraffin products have tariff benefits in the United States and Europe due to FTA. If you have any questions, please contact Sun Park at sypark@isugermany.de or Andy Shin at sws@isu.co.kr.