APPAREL

PCM-enhanced racewear joins the NASCAR circuit

Heat-absorbing undergarments developed by a British startup for use in auto racing are keeping NASCAR drivers cool this season.

Racewear developed by Walero of Cambridge, England, combines a flame-retardant yarn called Protal with a yarn embedded with Outlast Thermocules. The combination enhances driver comfort and performance while conforming to safety standards set by the International Automobile Federation, the sanctioning body of international motorsports, and the U.S.-based SFI Foundation.

Racewear developed by Walero of Cambridge, England, combines a flame-retardant yarn called Protal with a yarn embedded with Outlast Thermocules. The combination enhances driver comfort and performance while conforming to safety standards set by the International Automobile Federation, the sanctioning body of international motorsports, and the U.S.-based SFI Foundation.

Walero racewear has been adopted by drivers in all levels of racing since it hit the market in 2015, including IndyCar and the European Rally Championship. Walero was founded in 2014 by amateur racer Fiona James. She answered questions about her company by e-mail.

Q: What inspired you to pursue creation of temperature-regulating undergarments?

A: “I am a race driver. One day I sat sweating in the car in my usual hot, itchy uncomfortable Nomex on the grid and wondered why I couldn’t be wearing something more comfortable. As a race driver you are required to wear a lot of PPE due to the potential for fires and it is also incredibly hot in the car (even in open cockpit cars due to the aerodynamics). It’s not unusual to have temperatures well in excess of 50 degrees C and that’s while wearing several layers of flame-retardant fabric to protect you in the event of a fire, as well as a helmet. You’re also expected to perform at your best at very high speeds (in the GT4 racing I do, we can be reaching speeds of almost 190 mph; GT3 and single seater is faster still) and at times in exceedingly close proximity to other cars, often inches away from each other whilst battling for position.

“Needless to say, heat stress is a big problem for race drivers. It’s not unusual for the pros to train in heat chambers, and I have trained in layers of clothes myself. I would think most people involved in racing can tell you a story about a driver getting out of the car hallucinating, or collapsing when they get out of the car at the end of a stint due to dehydration or heat stress.

“All this meant that I wanted to find a solution that was more comfortable than the usual itchy, hot and uncomfortable Nomex and that also helped address the heat stress problems we encounter. Air-conditioning units can be expensive as well as adding a lot of weight and drawing power meaning a loss of speed so I really wanted to find a solution which was part of the kit a driver is already required to wear, and Outlast came up. I approached the UK agent who loved the idea and Outlast have been really supportive in helping us get off the ground. We now supply worldwide to drivers, mechanics and officials of all levels from DTM to NASCAR.”

Q: Tell me about the PCM used in the Outlast fabric.

A: “The melt peak (max) is 22 degrees C to 33 degrees C. The heat storage capacity is > 10 joules per gram.”

Q: Has the heat-regulating fabric been modified since the undergarments were first introduced in 2015?

A: “We are still using the same fabric with the same mix of yarn that we initially launched with, but we are currently working on a new fabric to comply with the new regulations (homologation) specified by the worldwide governing body, the FIA.

“We have done some testing with John Beeson at Cranfield University in their amazing simulator and also a performance coach who has worked with the highest level drivers in F1, Dean Fouache. We put a pro driver in a simulator with a controlled temperature of 32 degrees C, as this is the maximum allowed in the World Endurance Championship. These tests showed fantastic benefits of Walero compared to the standard Nomex products out there due to the PCM we utilise. The driver was shown to have a significantly reduced heart rate (average of 100bpm compared to 108 bpm), reduced sweat production by 40%, respiration rates were also significantly reduced.

“Importantly, the driver’s temperature rose considerably slower wearing Walero. At the end of the hour long test, his temperature was 0.9 degrees C lower than when wearing a competitors motorsports base layers. This means that cognitive function and reactions stay sharper and more consistent for longer as heat stress causes poor cognitive function, slower reaction times and decreased muscle endurance. Even a 2% dehydration level can cause significant performance loss. Twenty minutes into the test, the driver’s temperature had risen by 1 degree C in the standard Nomex, compared to just 0.2 degrees in Walero.

“Importantly, the driver’s temperature rose considerably slower wearing Walero. At the end of the hour long test, his temperature was 0.9 degrees C lower than when wearing a competitors motorsports base layers. This means that cognitive function and reactions stay sharper and more consistent for longer as heat stress causes poor cognitive function, slower reaction times and decreased muscle endurance. Even a 2% dehydration level can cause significant performance loss. Twenty minutes into the test, the driver’s temperature had risen by 1 degree C in the standard Nomex, compared to just 0.2 degrees in Walero.

“This all translated into more consistent lap times through increased consistency in brake points, more consistent turn in points, less fatigue so better concentration.”

Q: What were the biggest challenges in meeting motorsport safety regulations?

A: “We have been lucky to work with some really helpful and knowledgeable suppliers and we actually passed the testing first time round with our original core range. I might be biased, but Walero is far more comfortable than the usual Nomex – so much so that people have been known to wear our race base layers as PJs!

“The new homologation has proven a bit more challenging as we now have to comply with a heat transfer test and the PCM almost works against the way the test works. Covid and Brexit haven’t really helped the process either so we are admittedly quite behind with this development. However we are almost there and I’m really pleased with how the solution is shaping up. We will still be able to supply a technologically advanced product offering drivers an extremely comfortable solution whilst still providing the performance benefits proven in our existing range.“We have already successfully passed the testing for this new homologation with our long awaited socks, which will be launched shortly.”

Q: What’s the origin of the company name, Walero?

A: “Walero (pronounced the German way, as Valero) originated from my horse of a lifetime, Active Walero. He was, at the time, the highest scoring British horse abroad and helped Great Britain to its first dressage medal in 17 years at the European Championships. Naming the new company after him seemed fitting as they are both game changers in their class.”

Q: What’s next for Walero? Have you explored the potential for adapting Walero undergarments for use in other sports?

A: “I have a list as long as my arm! People already wear the existing Walero motorsports range for hiking, cycling, skiing, climbing, shooting and general training, so its benefits are already acknowledged and loved by people who wear our kit. All I will say at this point is watch this space for some news in the near future.”

PATENTS

Phase change insulation material for containers

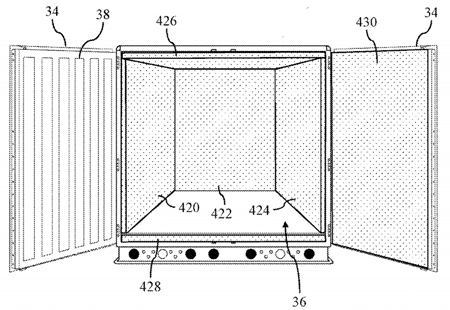

U.S. patent application 20210206565 (applicant Doubleday Acquisitions LLC, (Moraine, Ohio):

“Phase change materials (PCM) such as a liquid salt hydrate may be stored in capsules of various sizes and applied to fabrics and fibers to fabricate PCM features that provide passive temperature control for shipping containers and goods. In one implementation, PCM fabric covers may be placed over palletized cargo and over individual goods. Modular fabric pieces may be combined and interconnected to cover goods. Fabric covers may emphasize thermal performance over comfort or aesthetics when selecting microcapsule size and coating materials. In another implementation, PCM capsules may be combined with fiber filler, shaped as desired, and sealed within an exterior skin to produce rigid PCM panels having various shapes. Panels may be used to line interiors or exteriors of shipping containers or goods. Panels may be shaped to include contours that fit snugly against a desired surface, or to include interior portions in which goods can be fit into.”

“Phase change materials (PCM) such as a liquid salt hydrate may be stored in capsules of various sizes and applied to fabrics and fibers to fabricate PCM features that provide passive temperature control for shipping containers and goods. In one implementation, PCM fabric covers may be placed over palletized cargo and over individual goods. Modular fabric pieces may be combined and interconnected to cover goods. Fabric covers may emphasize thermal performance over comfort or aesthetics when selecting microcapsule size and coating materials. In another implementation, PCM capsules may be combined with fiber filler, shaped as desired, and sealed within an exterior skin to produce rigid PCM panels having various shapes. Panels may be used to line interiors or exteriors of shipping containers or goods. Panels may be shaped to include contours that fit snugly against a desired surface, or to include interior portions in which goods can be fit into.”

Viscoelastic polyurethane foam with PCM coating

U.S. patent application 20210206937 (applicants Dow Global Technologies LLC, Midland, Mich., and Rohm and Haas Co., Collegeville, Penn.):

“A coated viscoelastic polyurethane foam includes a viscoelastic polyurethane foam having the coating thereon, the viscoelastic polyurethane foam having a resiliency of less than or equal to 20% as measured according to ASTM D3574, and a coating material on and embedded within the viscoelastic polyurethane foam, the coating material including an aqueous polymer emulsion and an encapsulated phase change material.”

Phase change mechanically deformable cooling device

U.S. patent application 20210212236 (inventors Stephen Sang Geun Oh and Ki-yong Lee, Seoul, South Korea):

“The present invention comprises: a base receiving heat from a heat source; a hollow cylinder-shaped fixed cylinder fixedly receiving the heat from the base, an opening thereof being closed by the base; fixed fins fixedly provided at the fixed cylinder to receive the heat from the fixed cylinder; a piston slidably blocking the inside of the fixed cylinder forming an accommodation chamber for a phase change material; and an elastic member for applying force toward the base with respect to the piston, wherein at low temperature heat, the phase change material changes a phase in a volume reducing direction, and the piston is returned to a backward position at the side of the base, and at high temperature heat, the phase change material changes the phase in a volume increasing direction, and the piston is operated to move from the backward position to a forward position.”

“The present invention comprises: a base receiving heat from a heat source; a hollow cylinder-shaped fixed cylinder fixedly receiving the heat from the base, an opening thereof being closed by the base; fixed fins fixedly provided at the fixed cylinder to receive the heat from the fixed cylinder; a piston slidably blocking the inside of the fixed cylinder forming an accommodation chamber for a phase change material; and an elastic member for applying force toward the base with respect to the piston, wherein at low temperature heat, the phase change material changes a phase in a volume reducing direction, and the piston is returned to a backward position at the side of the base, and at high temperature heat, the phase change material changes the phase in a volume increasing direction, and the piston is operated to move from the backward position to a forward position.”

Rotor cooling system

U.S. patent application 20210215439 (inventor Sanjay K. Roy, Palmetto Bay, Fla.):

“This invention relates to temperature control of rotating shafts or assemblies to ensure proper operation and high reliability. Though it is particularly well suited for cooling high power, compact motors used in automotive applications, it can also be used to dissipate heat efficiently from other rotating assemblies to ensure that their temperatures remain within acceptable limits. The invention achieves this by utilizing a rotating heat pipe that incorporates a solid-liquid phase change material as the heat transfer/transport material. In addition, it comprises a scraped surface heat exchange mechanism at the heat dissipation region to allow for high cooling rates as required.”

More U.S. patent applications:

Energy storage systems (Sunamp Ltd., East Lothian, Great Britain) | Phase change cooling module and battery pack (Korea Institute of Machinery & Materials, Daejeon, South Korea) | PCM-based heat exchanger (Ecole Polytechnique Federale De Lausanne, Lausanne, Switzerland) | Mattress assemblies (Dreamwell Ltd., Doraville, Georgia) | Liquid metal-cooled nuclear reactor with passive residual power removal system (Commissariat a l’Energie Atomique et aux Energies Alternatives, Paris, France) | Transport container for temperature-sensitive goods (REP IP AG, Zug, Switzerland) | Cooling filter rod, application thereof and cigarette (China Tobacco Hunan Industrial Co. Ltd., Changsha, China) | Flexible cooling system with thermal energy storage (Rocky Research, Boulder City, Nevada) | Roasting system (La Bomba SPRL, Hamme-Mille, Belgium) | PCM-integrated insulation (University of North Texas, Dallas, Texas)

IN BRIEF

• CAVU Group, parent of Microtek Laboratories of Dayton, Ohio, is partnering with the University of Glasgow and Middle East Technical University in a smart building materials initiative. The project is focused on the development of sustainable building materials that will advance building energy efficiency and enhance occupant thermal comfort. CAVU will donate a supply of phase change materials (including Nextek and Micronal), along with product coaching, technical support, testing services, differential scanning calorimetry analysis and development support. “The support and experience provided by CAVU will play a key role in meeting the complex challenges of integrating PCM technology into building material applications,” said Cise Unluer of the University of Glasgow.

• Synhelion and the Swiss Federal Laboratories for Materials Science and Technology (EMPA) are collaborating on the further development of a high-temperature energy storage solution. Innosuisse, the Swiss innovation agency, is funding the project. EMPA says the project “will enable the cost-effective and scalable storage of high-temperature solar heat at over 1,000° C for the first time.”

• Alumina Energy is one of four companies selected for Halliburton Labs‘ Clean Energy Initiative. Alumina’s packed bed thermal energy storage technology is designed to turn renewable energy into a reliable and efficient source of heat and power.

• Energy storage dryers developed by Pluss Advanced Technologies are helping farmers in northeastern India earn more income and reduce food waste. The Aagun dryer uses phase change material to store solar energy and provide a reliable 24×7 heat source for drying fish, fruits, cooked produce and grains.

• 1414 Degrees of Australia has appointed oil and gas executive Matthew Squire as its chief executive officer, less than a month after managing director Jamie Simmons left the company following an investigation into allegations of workplace misconduct.

• MachPhy Solutions of Bhubaneswar, India, is one of 17 winners in the third edition of the Social Alpha energy challenge “Techtonic- Innovations in Clean Energy.” The startups will receive support in product design, testing and development. MachPhy uses phase change materials and nanomaterials in its hybrid cooling system.

• The U.S. Air Force has selected Rhea Space Activity for a Small Business Innovation Research award. The Washington D.C.-based startup is investigating a bi-modal, solar-thermal propulsion system that would provide rapid repositioning capabilities for a deep space communications spacecraft. The propulsion system uses large solar concentrators to heat up a tungsten block, melting encapsulated boron in the tungsten and storing significant amounts of energy in the phase change from solid to liquid. “Once fully charged,” Rhea says, “the tungsten block vaporizes propellant at temperatures hot enough to melt steel and generates enough thrust to perform an impulsive burn.”

• Holli Threlkeld, who earned her master’s degree in chemistry from the University of Georgia, has joined Alexium International as an R&D chemist.

• Cathay Pacific Cargo has added Sonoco ThermoSafe‘s passive Pegasus ULD container and Envirotainer’s active Releye RLP container as options for customers who need to ship temperature-sensitive vaccines and life-science supplies by air.

• German startup KraftBlock is among companies shortlisted for the New Energy Challenge 2021. KraftBlock’s high-temperature energy storage systems consists of 85% recycled raw materials and is designed to withstand temperatures between 350 C° and 1,300° C.

RESEARCH ROUNDUP

From Chemical Engineering Journal:

• Composite phase change material with room-temperature-flexibility for battery thermal management

From Processes:

From Building and Environment:

From ACS Omega:

From Journal of Engineered Fibers and Fabrics:

From Energy and Buildings:

From Applied Thermal Engineering:

• Enhanced heat transfer in a PCM shell-and-tube thermal energy storage system

• Phase change behaviour study of PCM tanks partially filled with graphite foam

From Geothermics:

From Renewable Energy:

From Materials Chemistry and Physics:

From Journal of Applied Polymer Science:

• Effects of thickeners on thermophysical properties of Alum as phase change material for energy storage

• PCM nanofibrous composites based on PEG/PVA incorporated by TiO2/Ag nanoparticles for thermal energy management

• Sustainable lignin-based polyols as promising thermal energy storage materials

From RSC Advances:

• Preparation and properties of capric acid–stearic acid-based ternary phase change materials

From Construction and Building Materials:

From Carbohydrate Polymers:

From Scientific Reports:

From Journal of Energy Resources Technology:

• Micro encapsulated phase change material for the application in thermal energy storage

From Solar Energy Materials and Solar Cells:

• Preparation, characterization and performance of paraffin/sepiolite composites as novel shape-stabilized phase change materials for thermal energy storage

• Characterization of demolition waste powder to be processed as sensible thermal energy storage material

• Nanoencapsulation of binary nitrate molten salts for thermal energy storage: Synthesis, thermal performance, and thermal reliability

From Journal of Energy Storage:

• Hybrid cooling based battery thermal management using composite phase change materials and forced convection

• Design and preparation of Ag modified expanded graphite based composite phase change materials with enhanced thermal conductivity and light-to-thermal properties

• Experimental investigation on the effects of phase change material and different ventilation modes on the thermal storage, space heating and energy consumption characteristics of ventilated mortar blocks

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,600 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,600 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Shahab Keshavarz, Ph.D, thermal energy storage engineer, Columbia, Missouri; Schuster Volker, director of research and development at Outlast Europe, Germany; Vivek Sharma, associate supply chain and procurement manager at Pluss Advanced Technologies, Bawal, India; Jon Nakagawa, founder, president and CEO at Marathon Products Inc., San Leandro, Calif.; and Akhan Tleoubaev, senior scientist at TA Instruments, Wakefield, Mass.

Longtime member Iftekhar Ahmed, director of thermal engineering at CAVU Group, posted links to a couple of interesting research papers: PCM use in microgravity applications and Alleviating heat stress in MS patients.

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at info@pcm-ral.de.

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at info@pcm-ral.de.

Axiotherm GmbH | Croda Europe Ltd. | ISU Chemical Co. Ltd. | RuhrTech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | Sunamp Ltd. | va-Q-tec AG