AGRICULTURE

PCM-based cold storage concept under development in Uganda

Ecolife Foods, a female-led social enterprise in Uganda, is looking for experts in plant-based phase change materials to advise on the development of a new version of its off-grid cold storage room.

Ecolife’s existing Cold Store, developed in partnership with Ugandan farmers, relies on batteries and a generator to keep fresh produce cold. Last fall, Ecolife was awarded first place — and $10,000 — in the Siemens Innovate for Impact design challenge to develop a PCM-equipped version of the Cold Store.

“To this end,” said Kyle Gaiser, Ecolife’s technical adviser, “we are exploring plant-based PCMs that can be tuned via hydrogenation to our target temperature, 6-8º C.”

The organization is focusing on locally sourced materials, such as palm oil, corn oil, soybean oil and tallow.

“I see a very real opportunity to bring about social and environmental change to the smallholder agricultural sector, quite literally from the ground up,” Gaiser said of the project. “I am excited by the prospect of leveraging international expertise and local leadership to bring about new ideas and solutions.”

If you’re interested in providing PCM expertise on this project, contact Gaiser (kyle.gaiser@gmail.com) or Ecolife co-founder Hadijah Nantambi (hadijahns15@gmail.com).

PATENTS

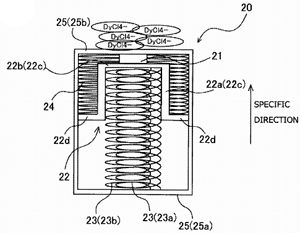

Wall panel

U.S. patent application 20210079662 (applicant Max Life LLC, Salisbury, N.C.):

“A wall panel may have a rigid layer, a first insulation layer made from a two-part rigid urethane pour foam, and a second insulation layer made from a phase change material. The first insulation layer may be chemically bonded to the rigid layer and may also be bonded to the phase change layer. The first insulation layer may be positioned between the second insulation layer and the rigid layer. The rigid layer may be a finished surface or a veneer layer may be applied to the rigid layer.”

Mobile air conditioner

U.S. patent application 20210088265 (applicant Midea Group Co. Ltd., Foshan, China):

“A mobile air conditioner, comprising: a first heat exchanger, having a first interface and a second interface for a refrigerant to enter and exit; a phase-change energy storage heat exchange device, including a second heat exchanger and a phase-change energy storage working medium, wherein the second heat exchanger and the phase-change energy storage working medium may exchange heat therebetween, and the second heat exchanger has a third interface and a fourth interface for the refrigerant to enter and exit; a first refrigerant pipeline, connected to the first interface and the third interface; and a second refrigerant pipeline, connected to the second interface and the fourth interface.”

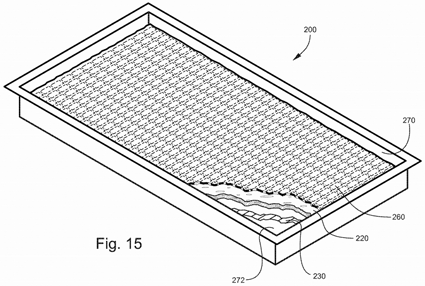

Latent heat storage body

U.S. patent application 20210087447 (applicant Yazaki Energy System Corp., Tokyo, Japan):

“This latent heat storage body is provided with: a latent heat storage material; and a temperature-sensitive material exhibiting different functions at a temperature equal to or higher than a specific temperature and at a temperature lower than the specific temperature, in which a phase change temperature is changed by using the function of the temperature-sensitive material according to ambient temperature. This latent heat storage body is characterized in that: the phase change temperature is set, by the function of the temperature-sensitive material when the ambient temperature is lower than the specific temperature, to one among a low temperature setting and a high temperature setting having a higher temperature than the low temperature setting.”

More U.S. patent applications:

Casing for battery pack (Contemporary Amperex Technology Co. Ltd., Ningde, China) | Rechargeable passive cooled refrigerated cargo box (Carrier Corp., Palm Beach Gardens, Fla.) | Energy storage device (Guangxi Banshida Green Building Energy Saving Technology Co. Ltd., Liuzhou, China) | Battery module with enhanced cooling efficiency (LG Chem, Seoul, South Korea) | Thermal liquid container system (University of Missouri, Columbia, Mo.) | Wax formulations having improved release characteristics (Firmenich SA, Geneva, Switzerland) | LED luminaire device with active cooling system (Signify Holding BV, Eindhoven, Netherlands)

IN BRIEF

• Pluss Advanced Technologies of Gurgaon, India, has been granted a U.S. patent for its Celsure temperature-controlled box. The shipper uses a variety of phase change materials to maintain temperatures from -77°C to +89°C, for times ranging for a few hours to a few days.

• The 16th International Conference on Advanced Building Skins, to be held Oct. 21-22 in Bern, Switzerland, has issued a call for papers. Topics include “Thermal performance of phase change materials for the building skin,” “Eco-materials for a sustainable building skin” and “Models, tools and simulations for sustainable buildings.” The deadline for submitting a proposal is April 20.

• Sonoco ThermoSafe of Arlington Heights, Ill., has an opening for a Market Quality Manager. The successful candidate will lead a team of plant quality managers in the temperature assurance packaging market segment.

• Sunamp Ltd. of Edinburgh, Scotland, has posted several openings on its website: CAD engineer; electronic and control engineer; project engineer; test engineer; field services engineer; and digital marketing manager.

• In a small-scale study at Radboud University Medical Centre in Netherlands earlier this year, Inuteq cooling vests were shown to significantly reduce nurses’ perception of heat strain. The study, conducted by the Netherlands Organization for Applied Scientific Research, monitored seventeen nurses from COVID care wards over two days, both wearing and not wearing the cooling vests, which feature CrodaTherm phase change material. The study measured body temperature and heart rate, as well as subjective measures, such as comfort and heat experience. The results, now published in the journal Temperature, showed that wearing the vest had little effect on core body temperature, but reduced the perception of heat strain, probably due to improved comfort at skin-level.

• CAVU Group of Dayton, Ohio, has completed acquisition of Latent Heat Solutions of Golden, Colo. Under the agreement, CAVU takes ownership of LHS assets, resources and customer contracts from CoorsTEK Inc. LHS specializes in thermal management solutions for the commercial battery energy storage sector along with temperature stabilization of thermosensitive components and surfaces. The merged business will operate as one of the CAVU Group brands, joining American Thermal Instruments and Microtek Laboratories.

•ISU Chemical Co. Ltd. of Seoul, South Korea, is the newest member of the RAL Quality Association PCM. ISU’s high-purity linear paraffins cover a temperature range from -60 °C to +19 °C. Application areas include cold chain and packaging; building and construction; HVAC; and thermal energy storage. ISU representatives introduced the company at the association’s web conference in March. The association’s next general assembly will be held Nov. 11 as a hybrid meeting (face-to-face plus web conference) in Düsseldorf, Germany.

RESEARCH ROUNDUP

From Renewable Energy:

• The heat capacity of low-temperature phase change materials (PCM) applied in thermal energy storage systems

• Experimental evaluation of a hybrid photovoltaic and thermal solar energy collector with integrated phase change material (PVT-PCM) in comparison with a traditional photovoltaic (PV) module

From Energy and Buildings:

From Energy Conversion and Management:

• Assessment of a novel phase change material-based thermal caisson for geothermal heating and cooling

From Renewable and Sustainable Energy Reviews:

From Sustainable Energy Technologies and Assessments:

• A new integrated system with thermal energy storage for five useful outputs: A case study

• Experimental evaluation of the optimal position of a macroencapsulated phase change material incorporated composite roof under hot climate conditions

From Solar Energy:

From Building and Environment:

From White Rose eTheses Online:

• High Density Heat Storage for Homes (Ph.D. thesis, University of Sheffield)

From Case Studies in Construction Materials:

• Effect of scale-up on the properties of PCM-impregnated tiles containing glass scraps

From International Journal of Energy Research:

From International Journal of Heat and Mass Transfer:

From Applied Energy:

From AIP Conference Proceedings:

• Reducing temperature fluctuation of refrigeration system by incorporating nano-phase change materials

• Future trends in CSP with an emphasis on thermal energy storage

From Journal of Energy Storage:

• Numerical investigation of the optimization of phase change thermal storage units with air as heat transfer fluid

• A first principles framework to predict the transient performance of latent heat thermal energy storage

• Investigation of storage rotation effect on phase change material charging process in latent heat thermal energy storage system

From Energy & Fuels:

From Journal of Cleaner Production:

• A novel 24-h day-night operational solar thermoelectric generator using phase change materials

From Materials:

• Thermal Energy Storage by the Encapsulation of Phase Change Materials in Building Elements—A Review

From Journal of Materials Research and Technology:

From International Journal of Thermofluids:

• Phase Change Materials in Solar Domestic Hot Water Systems: A review

From Fluids:

• HVDC Converter Cooling System with a Phase Change Dispersion

From Energy Storage:

• Experimental charging/discharging studies of organic phase change materials for cold thermal energy storage application

• Segregation/cycling effects on thermo‐physical properties of salt hydrate phase change materials

From Thermal Science and Engineering Progress:

From ACS Omega:

From Journal of Applied Polymer Science:

• Fabrication and performance of shape‐stable phase change materials based on epoxy group crosslinking

From Solar Energy Materials and Solar Cells:

From Journal of Natural Fibers:

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,600 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Alik Miller, manufacturing manager at AeroSafe Global, Rochester, N.Y.; Lauren Davis, senior marketing manager at CAVU Group, Dayton, Ohio; Eric van der Zwart, team manager at Topa Thermal BV, Voorhout, Netherlands; Emma Payne, packaging engineer at SCA Cool Logistics, Luton, England; Christoph Rathgeber, assistant head of the thermal energy storage group at ZAE Bayern, Garching, Germany; Ross Wahl, operations supervisor at Encapsys, Oxford, Wis.; Lisa Dufresne, manager at GC Ventures America, Boston, Mass.; Yaniv Abitan, cold chain packaging specialist at Insulpack Group Ltd., Jerusalem, Israel; and Geoffrey Glibas, business development executive with Jones Tech, Cupertino, Calif. Geoffrey writes:

“I have a new request from a customer looking for a heat storage PCM with very high enthalpy and a melting point of 50 – 60°C. Do any of you have a referral for materials that meet this criteria?”

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at info@pcm-ral.de.

Axiotherm GmbH | Croda Europe Ltd. | Global Energy Systems Europe | ISU Chemical Co. Ltd. | RuhrTech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | Sunamp Ltd. | va-Q-tec AG