APPLICATIONS

PCMs: A mature technology with a wide range of uses

The Journal of Energy Storage has published a comprehensive overview of the range of applications and commercial products powered by phase change materials.

The article, researched and written with the support of the RAL Quality Association PCM, “shows that PCM are used in many commercial applications already, and in many fields” and demonstrates their enormous potential in applications still needing significant R&D.

PCM products have been commercialized in many areas. Here are some examples listed in the article:

Building materials: “The company GlassX AG produces translucent, thin glass elements, which are filled with PCM and thus can store as much heat as a concrete wall. The translucent elements can absorb solar radiation and internal heat, and also serve as design objects.”

Space heating and cooling: “Sunamp‘s UniQ range Heat Battery … uses an internal heat exchanger for discharge. Charging the Heat Battery can be with different sources of energy, e.g. grid electricity, PV electricity, a gas boiler, or a high temperature heat pump. A different heat concept is used in the kraftBoxx storage by Axiotherm, where small stick-shaped PCM macro capsules (called HeatStixx) are filled in a hot water storage tank in loose bulk.”

Space heating and cooling: “Sunamp‘s UniQ range Heat Battery … uses an internal heat exchanger for discharge. Charging the Heat Battery can be with different sources of energy, e.g. grid electricity, PV electricity, a gas boiler, or a high temperature heat pump. A different heat concept is used in the kraftBoxx storage by Axiotherm, where small stick-shaped PCM macro capsules (called HeatStixx) are filled in a hot water storage tank in loose bulk.”

Cold chain: “Especially for very temperature sensitive products of high value, as is typically the case for pharmaceuticals and vaccines, the use of PCM has become the standard. Typically, companies cover this field of application with a range of products,” such as Pluss Advanced Technologies’ PronGO grocery bag and shipping containers made by Cold Chain Technologies, va-Q-tec AG, Cryopack, Sonoco ThermoSafe, Hangzhou Ruhr New Material Technology Co. and Climator Sweden AB.

Transportation: PCM-filled metallic plates developed by Pluss are mounted inside delivery trucks to keep payloads cold. The plates are charged by an external electrically operated compressor during non-operational hours.

Protective garments: “Protective garments are used for a variety of activities and ambient conditions, ranging from protection against overheating or cooling of the body at higher physical activity e.g. during hard work, when exposed to excessive ambient heat or cold e.g. outdoors, but also when otherwise protective gear makes the temperature regulation of the body difficult.” Glacier Tek, Inuteq and Pluss are active in this area.

Apparel: “PCM takes up and releases heat depending on the temperature of the body and the ambient and thereby improves the human comfort feeling, specifically to avoid freezing or sweating.” Schoeller Textil AG, Microtek Laboratories Inc. and Outlast Technologies are active in this area.

Mattresses and bedding: “The integration of PCM into sleeping equipment is again typically using microencapsulated organic PCM, to regulate the body’s skin temperature.” Microtek and Outlast are also active in this area.

Medical applications: “Applications to the human body are heat or cold therapy in general, for example heat cushions for physiotherapy or rheumatism, blankets to avoid hypothermia, or cooling packs used after surgery, accidents, or sportive stress. Incubators, warmers, or coolers are specific applications for newborns.” PureTemp, Rubitherm Technologies and Pluss are active in this area.

Automotive: “Thermal management of battery packs with many batteries is of key importance for electric vehicles. Thermal management in this case comprises the prevention of overheating during charge and discharge.” AllCell Technologies is active in this area.

Automotive: “Thermal management of battery packs with many batteries is of key importance for electric vehicles. Thermal management in this case comprises the prevention of overheating during charge and discharge.” AllCell Technologies is active in this area.

Prosthetics: “The Alpha SmartTemp® Liner uses Outlast PCM to absorb and store heat as it builds up in a residual limb, delaying the onset of sweat before it starts. Releasing stored heat as the body cools, the liner stabilizes skin temperature, keeping an amputee comfortable.”

The full article, “PCM products and their fields of application – An overview of the state in 2020/2021,” is available for free download on the ScienceDirect website. The authors are Harald Mehling, Michael Brütting and Thomas Haussmann. Mehling is a consultant to Pluss Advanced Technologies and the RAL Quality Association PCM. Brütting works at the ZAE Bayern, a monitoring institute of the association. Haussmann works at FhG-ISE, a monitoring institute of the association.

PATENTS

Phase change material

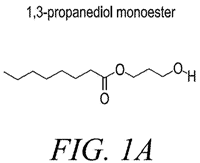

U.S. patent application 20220064511 (applicant DuPont Industrial Biosciences USA, Wilmington, Delaware):

“This invention describes a phase change material being 1,3-propanediol ester where the 1,3-propanediol ester can be either a 1,3-propanediol monoester or a 1,3-propanediol diester. This invention further describes the use of 1,3-propanediol ester as a phase change material for releasing or absorbing latent heat during melting or crystallization. This invention also describes the use of the phase change material for use in non-food and food applications.”

Thermal management phase change composition

U.S. patent application 20220081567 (applicant Rogers Corp., Chandler, Arizona):

“A phase-change composition comprises a homogeneous mixture of a thermoplastic polymer composition; and a phase-change material; wherein the phase-change composition has a viscosity of less than 100,000 centipoise, or less than 55,000 centipoise, or less than 30,000 centipoise, or less than 20,000 centipoise, or less than 10,000 centipoise, or less than 3000 centipoise at a temperature greater than or equal to 120° C. and is a gel at a temperature less than or equal to 100° C., or less than or equal to 80° C., or less than or equal to 50° C.”

More U.S. patent applications:

Thermally insulated containers (DGP Intelsius Ltd., York, Great Britain) | Amine modified polysaccharide urethane/urea microcapsules

(Encapsys LLC, Appleton, Wis.) | Method and system for battery protection (Milwaukee Electric Tool Corp., Brookfield, Wis.) | Method of controlling thermal energy storage (Rolls-Royce North American Technologies Inc., Indianapolis, Indiana) | Heat storage using phase change material coated with nanoparticles (SaltX Technology AB, Hägersten, Sweden) | Cooling cigarette filter and smoking product (China Tobacco Hunan Industrial Co. Ltd., Changsha, China) | Phase change heat storage rubber (Liqiang Zhang, Huizhou, China)

IN BRIEF

• President Biden has nominated Dr. Evelyn N. Wang, right, as director of the Advanced Research Projects Agency-Energy (ARPA-E) at the U.S. Department of Energy. Wang is the head of the mechanical engineering department at the Massachusetts Institute of Technology. She is noted for her research in phase-change heat transfer in electronics, thermal batteries, solar thermal energy conversion and desalination devices.

• President Biden has nominated Dr. Evelyn N. Wang, right, as director of the Advanced Research Projects Agency-Energy (ARPA-E) at the U.S. Department of Energy. Wang is the head of the mechanical engineering department at the Massachusetts Institute of Technology. She is noted for her research in phase-change heat transfer in electronics, thermal batteries, solar thermal energy conversion and desalination devices.

• Swedish startup Azelio AB is seeking U.S. certification for its TES.POD product, a long-duration thermal energy storage technology. The certification project will be conducted in Baton Rouge, La., in partnermship with MMR Group of Baton Rouge. TES.POD technology stores energy as 600°C heat in a phase change material made of a recycled aluminium alloy. The heat drives a Stirling engine, which converts the energy into electricity.

• Researchers at Martin Luther University Halle-Wittenberg and the University of Leipzig have developed a new heat storage material that could significantly improve the energy efficiency of buildings. The material can be used to store surplus heat and release it when needed. Unlike existing materials, Science Daily reports, “the new one can absorb significantly more heat, is more stable, and is made of harmless substances.”

• Sonoco ThermoSafe reports that its PCM-equipped shippers are being used to deliver temperature-sensitive medicine to patients on board charity hospital ships in Senegal.

• Erich Kisi, a professor of materials science at the University of Newcastle in Australia, says he has developed a pollution-free technology he calls “miscibility gaps alloy”: stackable blocks that can store thermal energy for use on demand. The technology consists of alloys that melt and freeze to store and release heat. The alloys are embedded in a matrix to preserve the structure of the material.

• Viking Cold Solutions’ thermal energy storage technology has been validated in a two-year evaluation by environmental consulting firm D+R International on behalf of Southern California Edison. The evaluation, carried out at a food service distributor in Southern California, determined that “phase change materials combined with intelligent controls significantly improved energy efficiency and demand management capabilities for cold storage facilities,” according the Houston-based company.

• In a LinkedIn post, Rubitherm Technologies reports that the EU’s Horizon 2020 iclimabuilt project, a consortium of 27 partners in 14 countries, has completed its first year. The partners are working to develop energy-efficient building envelope materials. The company wrote: “Rubitherm is participating with its pilot line for optimization of in-process control of aluminum-macroencapsulated panels filled with the desired PCM namely ‘compact storage module (CSM)’ developed by Rubitherm. Within iclimabuilt, full traceability of the panels (metal part and PCM production), based on unique QR code for identification, humidity control and panel tightness testing are implemented. By conducting this, quality control and PCM production time will be shortened. Thus, transfer into larger scale production, decreasing energy consumption as well as CO2 fingerprint reduction can be realized.”

• Thermal battery maker Sunamp Ltd. won first place in Futurebuild 2022‘s Big Innovation Pitch competition in London this month. Six finalists chosen from more than 90 entrants were given five minutes to pitch their innovations before a panel of judges. Toby Morris, right, specification sales manager at Sunamp, delivered the winning pitch.

• Thermal battery maker Sunamp Ltd. won first place in Futurebuild 2022‘s Big Innovation Pitch competition in London this month. Six finalists chosen from more than 90 entrants were given five minutes to pitch their innovations before a panel of judges. Toby Morris, right, specification sales manager at Sunamp, delivered the winning pitch.

• Presentations given at the 9th Swiss Symposium Thermal Energy Storage 2022 are now available on the Lucerne University of Applied Sciences and Arts website. Among the presenters were Luisa F. Cabeza of the University of Lleida and Poppy O‘Neill of the Lucerne University of Applied Sciences and Arts.

• Yotta Energy of Austin, Texas, has several job openings, including director of software engineering and vice president of engineering. Yotta’s SolarLeaf, a 1-kWh lithium-iron phosphate battery designed to be paired with rooftop solar panels, is equipped with phase change material to manage excess heat.

• Encapsys LLC of Appleton, Wis., which encapsulates phase change materials, fragrances and other materials, has a number of R&D openings: senior scientist, agriculture; formulation scientist; senior scientist, raw materials; new technology and innovation scientist; research lab technician; and senior analytical chemist.

RESEARCH ROUNDUP

From Journal of Energy Storage:

• Nano-enhanced phase change material for thermal comfort at skull and environment interface in riding helmets: An experimental investigation

• Salt hydrate phase change materials: Current state of art and the road ahead

• Experimental screening of salt hydrates for thermochemical energy storage for building heating application

• Improving system performance of the refrigeration unit using phase change material (PCM) for transport refrigerated vehicles: An experimental investigation in South China

• Fundamental structure-function relationships in vegetable oil based phase change materials: A critical review

• Analysis of cold thermal energy storage using phase change materials in freezers

From Applied Energy:

From ACS Applied Polymer Materials:

• Rapid UV-Curable Form-Stable Polyethylene-Glycol-Based Phase Change Material

From Solar Materials and Solar Cells:

• Construction of high thermal conductive boron Nitrid@Chitosan aerogel/ paraffin composite phase change material

• Facile microencapsulation of phase change material with organic silicon shell used for energy storage

From Applied Thermal Engineering:

• Performance analysis of phase-change material in battery thermal management with bionic leaf vein structure

• Incorporating phase change materials into glazing units for building applications: Current progress and challenges

• Experimental research of an ocean thermal engine with phase-change material

• Concept development and experimentation of a Phase Change Material (PCM) enhanced domestic hot water

• Performance optimization of sodium acetate trihydrate-based phase change material

From Construction and Building Materials:

From International Materials Reviews:

• Nano additive enhanced salt hydrate phase change materials for thermal energy storage

From Conference on Innovative Research in Applied Science, Engineering and Technology:

• Comparative study of different phase change materials for latent heat storage CSP application

From Journal of Building Engineering:

From Journal of Thermal Analysis and Calorimetry:

From Powder Technology:

From Cleaner Energy and Technology:

From Journal of Polymer Research:

• Composite polyester yarn with photothermal conversion and phase change properties

From Renewable Energy:

• Year-round energy and exergy performance investigation of a photovoltaic panel coupled with metal foam/phase change material composite

• Role of phase change materials in backfilling of flat-panels ground heat exchanger

From Materials Chemistry Frontiers:

From Journal of Food Process Engineering:

• Phase change material-assisted freezing of tuna: Impact on freezing process and thawing loss

From Materials:

• Cooling Effect of Phase Change Materials Applied in Undergarments of Mine Rescuers in Simulated Utility Conditions on Thermal Manikin

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,700 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,700 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Chen Li, professor at the University of South Carolina, Columbia, S.C.; Abdurrahman Khan, operations manager at DIQA Technologies Ltd., United Arab Emirates; Peter Nowicke, product analyst at Phase Change Solutions Inc., Asheboro, N.C.; Ingo Horger, senior business development manager, Europe, at Outlast Technologies GmbH, Heidenheim, Germany; Müyesser Selda Tözüm, lecturer at Usak University, Usak, Turkey; and Robert Battista, engineering manager at Modality Solutions, Houston, Texas.

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

Axiotherm GmbH | Croda Europe Ltd. | ISU Chemical Co. Ltd. | Ruhr Tech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | S.Lab Asia Inc. | Sunamp Ltd. | va-Q-tec AG

MEMBER SPOTLIGHT: AXIOTHERM GmbH | Eisenberg, Germany

Offering extensive experience in development and application planning, Axiotherm is a leading manufacturer and your expert partner for cost-efficient systems based on PCM and approved macro-encapsulations. Axiotherm offers more than 50 organic (ATP) and inorganic (ATS) high-performance PCM in a temperature range between -65°C to 120°C, also available in special macro-encapsulations for improved performance in practical applications. For information on the latest PCM developments for pharma logistics and cold chains, such as new inorganic alternatives ATS 5 or ATS 20, please contact Axiotherm.