TRANSPORTATION

EU-funded technologies increase EV driving range by 25% in test vehicle

Rubitherm Technologies GmbH was among more than a dozen organizations that played important roles in the European Union’s recently completed QUIET project, which set out to significantly increase the driving range of electric vehicles in hot and cold conditions.

The project, launched in October 2017, focused on three areas: improved energy management; lightweight materials with enhanced thermal insulation properties; and improved safety and comfort. The technologies developed over the course of the project were integrated and tested in a Honda Fit EV. The result: A lighter vehicle that uses less energy to heat and cool the passenger cabin, resulting in 25% increase in driving range in extreme conditions.

The project, launched in October 2017, focused on three areas: improved energy management; lightweight materials with enhanced thermal insulation properties; and improved safety and comfort. The technologies developed over the course of the project were integrated and tested in a Honda Fit EV. The result: A lighter vehicle that uses less energy to heat and cool the passenger cabin, resulting in 25% increase in driving range in extreme conditions.

Working with the Fraunhofer Institute for Manufacturing Technology and Advanced Materials, Rubitherm developed a PCM-based thermal energy storage system designed to recycle waste heat created by the electric powertrain and on-board charger. Their work is described in an open-access article, „PCM-Based Energy Storage System with High Power Output Using Open Porous Aluminum Foams.“

QUIET, short for QUalifying and Implementing a user-centric designed and EfficienT electric vehicle, was coordinated by the Austrian Institute of Technology. The project received 7 million euros in funding from the European Union’s Horizon 2020 research and innovation program. Details on the new technologies are being shared with vehicle manufacturers and suppliers.

Dr. Esther Kieseritzky, Rubitherm’s general manager, shared some thoughts on the project by email.

„The QUIET project aimed at changing and improving a lot of different parameters on an existing electric vehicle,“ she said. „From replacing heavy structures by lightweight components while increasing thermal comfort to integrating new technologies for enhanced energy efficiency and all that based on a user-centric approach. Adding a thermal storage was one building block of many and Rubitherm was responsible for this component.“

Q: Which thermal storage system described in the research paper — 26p or 4p — was used in the test car that achieved the desired range increase? Why was it chosen?A: „The 4p storage. It has the simpler internal structure and therefore – regarding the design – it is closer to what we would be looking at in a serial production. However, the heat transfer surface to the coolant is longer in the 26p storage. This was found to be important in some lab bench tests and will influence the final design as well.“

Q: Did Rubitherm face any notable challenges in developing the two systems?

A: „Material wise the challenge was to incorporate the PCM with a thickening agent in the foam structure. Here, it took some time to find a proper process based on multiple vacuum infiltration steps to reach the desired filling factor. The connection of the many part system was also quite demanding on lab scale. One of our first conclusions: a serial product should consist of one big foam part containing already the whole heat transfer piping.“

Q: The project achieved its goal of increasing EV driving range by at least 25% in hot and cold conditions. How much of the increase can be attributed to the thermal storage unit?

A: „As the vehicle was tested as a whole it is difficult to break that down for all individual changes that have been made. Generally, in cold conditions the thermal storage can contribute more than in hot weather.“

PATENTS

Thermoplastic shape-stable polymer compositions for storing thermal energy

U.S. patent application 20210130670 (applicant Carmel Olefins, Haifa, Israel):

„The invention provides shape-stable products for storing and releasing thermal energy, based on thermoplastic polymer compositions containing organic phase change materials (PCM) incorporated into a polymer matrix, the products withstanding multiple melting-crystallization cycles of the PCM while maintaining their shape, dimensions, and the thermal energy storage capacity.“

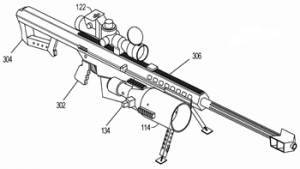

Laser weapon system

U.S. patent application 20210131768 (applicant Applied Research Associates Inc., Albuquerque, N.M.):

„A portable laser weapon system comprising: a laser generation module comprising a diode; a fiber optic cable coupled to the laser generation module; a laser emitting unit coupled to the fiber optic cable; and a heat mitigation module comprising: at least one reservoir containing a phase change material, at least one removable cooling pod containing a phase change material, or both, wherein heat generated by the laser generation module converts the phase change material from a first phase to a second phase.“

„A portable laser weapon system comprising: a laser generation module comprising a diode; a fiber optic cable coupled to the laser generation module; a laser emitting unit coupled to the fiber optic cable; and a heat mitigation module comprising: at least one reservoir containing a phase change material, at least one removable cooling pod containing a phase change material, or both, wherein heat generated by the laser generation module converts the phase change material from a first phase to a second phase.“

Thermally insulated packaging for shipping liquid in bottles

U.S. patent application 20210140697 (applicant Viking Cold Solutions, Houston, Texas):

„A thermally insulated structure for shipping goods, the structure including an insulated box having a goods receptacle and a phase change material module receptacle. The structure further including a phase change material module, and a set of vacuum panels configured to form an encapsulating layer around the insulated box.“

Phase change cosmetic composition

U.S. patent application 20210128449 (applicant Amorepacific Corp., Seoul, South Korea):

„One aspect of the present disclosure relates to a phase transfer cosmetic composition. According to the present disclosure, there can be provided a cosmetic composition which contains a wax having a melting point of 40 to 60° C. and an inulin-based surfactant, wherein the composition maintains a liquid state before applied to the skin and rubbed, and changes to a solid state when applied to the skin, can solve the problems in terms of hygiene and use because it is not used by scooping it by hand, and further, changes its phase to a solid state when applied to the skin and then rubbed, and thus, can solve the problem of dripping when applied to face or skin.“

More U.S. patent applications:

Heat exchanging liquid container (Hongbin Ma, Columbia, Mo.) | Container for storage and transportation of goods (Softbox Systems Ltd., Long Crendon, Great Britain) | Shape-stabilized PCM based on hierarchically porous calcium magnesium carbonate (King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia) | Seating system having pressure compensating fluid with thermal absorption and distribution properties (Sunrise Medical LLC, Fresno, Calif.) | Unit load device (Carrier Corp., Palm Beach Gardens, Fla.) | Insulating and cooling liquid container (Pierre Maurice Baston, Philadelphia, Penn.) | System and method for cooling a leading edge of a high speed vehicle (General Electric Co., Schenectady, N.Y.) | Heat storage in chemical reactors (Lummus Technology LLC, Bloomfield, N.J.) | Apparatus for controlling an experimental temperature of an experimental material (Arctoris Ltd., Oxford, Great Britain) | Evaporative cooling system and device (Mestek Inc., Westfield, Mass.) | Super-hybrid heat pump system and method (Melink Solar & Geothermal Inc., Milford, Ohio)

IN BRIEF

• Andreas Hauer, head of ZAE Bayern’s energy storage division, and Luisa Cabeza of the University of Lleida, Spain, are among the speakers at Enerstock 2021, to be held June 9-11. Cabeza’s keynote address is titled „Phase change materials: Still the starring technology of thermal energy storage? Current applications, perspectives and research gaps.“ Manikantan Kota, right, of Pluss Advanced Technologies will present research on „PCM absorbed exfoliated graphite/polymer composites for thermal management of lithium-ion batteries.“ RAL Quality Association PCM member Harald Mehling will present research on potential new reference materials for caloric measurements on PCM. Registration for the virtual conference, organized by Slovenia’s University of Ljubljana, remains open. The registration fee is 370 euros; for students, 170 euros.

• Andreas Hauer, head of ZAE Bayern’s energy storage division, and Luisa Cabeza of the University of Lleida, Spain, are among the speakers at Enerstock 2021, to be held June 9-11. Cabeza’s keynote address is titled „Phase change materials: Still the starring technology of thermal energy storage? Current applications, perspectives and research gaps.“ Manikantan Kota, right, of Pluss Advanced Technologies will present research on „PCM absorbed exfoliated graphite/polymer composites for thermal management of lithium-ion batteries.“ RAL Quality Association PCM member Harald Mehling will present research on potential new reference materials for caloric measurements on PCM. Registration for the virtual conference, organized by Slovenia’s University of Ljubljana, remains open. The registration fee is 370 euros; for students, 170 euros.

• Alexium International of Victoria, Australia, and Greer, S.C., reports that its new BioCool line of phase change material has earned the U.S. Department of Agriculture’s Biobased Product label. Chris Crawford, Alexium’s vice president for sales and marketing, says BioCool PCMs will be used in bedding, active wear and other applications. „A fairly broad range of temperatures are available as it pertains to home goods and personal apparel,“ Crawford said. „As we formulate to meet the needs of our customers, we continue to develop the product range to augment our legacy product line, Alexicool PCMs.“

• Sean Austerberry has joined Softbox Systems Ltd., Long Crendon, Great Britain, as director of research and product development.

• Gabor Mucsanyi has joined Pluss Advanced Technologies, Gurgaon, India, as operations manager.

• Thermal Custom Packaging of Hialeah, Fla., has developed transport totes for blood specimens, biological pharmaceuticals and COVID-19 vaccines. The insulated totes use phase change materials to keep sensitive materials at the desired temperatures.

• The development team at va-Q-tec AG, Wurzburg, Germany, has developed on short notice a special inlay for the company’s thermal transport solution va-Q-tray. The inlay simplifies the packaging and use of syringes filled COVID-19 vaccines, while ensuring that the vaccines are stored at optimal temperatures.

• Sunamp Ltd. has appointed Hank Torbert, right, as its new chair. Torbert is president of Alta Max LLC, a specialty packaging company based in New Orleans. „This is a very exciting appointment for Sunamp, and Hank is a very welcome addition to the board,“ said Sunamp CEO Andrew Bissell. „His extensive track record in growing businesses, along with his cross-sector board level experience and entrepreneurial flair is already proving very valuable to us.“ Torbert replaces Martin Bloom, who had served as chair since 2019.

• Sunamp Ltd. has appointed Hank Torbert, right, as its new chair. Torbert is president of Alta Max LLC, a specialty packaging company based in New Orleans. „This is a very exciting appointment for Sunamp, and Hank is a very welcome addition to the board,“ said Sunamp CEO Andrew Bissell. „His extensive track record in growing businesses, along with his cross-sector board level experience and entrepreneurial flair is already proving very valuable to us.“ Torbert replaces Martin Bloom, who had served as chair since 2019.

• The South Australian government has extended its Crown Sponsorship of 1414 Degrees‚ Aurora Energy project to support the construction of the project’s battery and thermal energy storage system. The Australian company also unveiled commercialization plans for its SiBox thermal energy storage technology, which harnesses the heat of molten silicon. A 1-megawatt-hour demonstration module is set to be commissioned in September 2022.

• Robotic floats powered by lithium-ion batteries are used to monitor the physical, chemical and geological characteristics of our oceans, a task critical to understanding the effects of climate change. But each year, thousands of these floats lose power and pollute the ocean floor. A company called Seatrec of Vista, Calif., has designed a sustainable alternative: a PCM-based generator system that harnesses the ocean’s own thermal energy to recharge itself.

RESEARCH ROUNDUP

From Journal of the European Ceramic Society:

From ChemSusChem:

• Guanidinium organic salts as phase change materials for renewable energy storage

From Materials Science for Energy Technologies:

From Energy Storage Science and Technology:

• Phase change materials for energy storage in cold-chain transportation

From International Journal of Heat and Mass Transfer:

From International Journal of Refrigeration:

• An exfoliated montmorillonite as the nanosheet nucleating agent in the subzero phase change material

From Journal of Thermal Analysis and Calorimetry:

From ACS Applied Polymer Materials:

From Construction and Building Materials:

• PCM-modified textile-reinforced concrete slab: A multiscale and multiphysics investigation

From Building and Environment:

From Energy Storage Materials:

From Renewable Energy:

• Experimental determination of thermal conductivity of fatty acid binary mixtures and their shape-stabilized composites

• Applicability assessment of stearic acid/palmitic acid binary eutectic phase change material in cooling pavement

• Development of novel form-stable phase change material (PCM) composite using recycled expanded glass for thermal energy storage in cementitious composite

From Materials Today: Proceedings:

• Application of phase change materials for cooling of solar photovoltaic panels: A review

• Thermal management of metal roof building using phase change material (PCM)

From Institute of Electrical and Electronics Engineers:

From Cellulose:

• Biodegradable thermoactive packaging using phase change material particles on cellulosic materials

From Structural and Multidisciplinary Optimization:

• Functionally graded optimisation of adsorption systems with phase change materials

From Energy & Fuels:

From Langmuir:

From Journal of Energy Storage:

• High internal phase emulsion templated-polystyrene/carbon nano fiber/hexadecanol composites phase change materials for thermal management applications

• Multicomponent bio-based fatty acids system as phase change material for low temperature energy storage

• Cycle test stability and corrosion evaluation of phase change materials used in thermal energy storage systems

From Chemical Engineering Journal:

• Fluorescent Thermochromic Wood-based Composite Phase Change Materials Based on Aggregation-induced Emission Carbon Dots for Visual Solar-Thermal Energy Conversion and Storage

• Thermoconductive n-alkane enables ultra-high shape/thermal stability, durability, and ambient thermal energy harvesting

From Energies:

• Heat Transfer by Natural Convection in a Square Enclosure Containing PCM Suspensions

From Solar Energy Materials and Solar Cells:

From Solar Energy:

• Thermal energy storage in fluidized bed using microencapsulated phase change materials

• Phase change thermal storage: Cooking with more power and versatility

From Applied Thermal Engineering:

From Energy:

• Perspectives on thermal energy storage research

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,600 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,600 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Abhishek Gautam, research scholar in solar thermal energy at the Indian Institute of Technology Roorkee; Evan Fleming, thermal/power architect and thermal materials researcher, Austin, Texas; Steve Wallace, principal scientist at Kevothermal LLC, Albuquerque, N.M.; Jialai Wang, professor of civil engineering at the University of Alabama, Tuscaloosa, Ala.; Daniël Rautenbach, R&D scientist at Sasol, Sasolburg, South Africa; Alireza Abdollahinik, building energy researcher, Tehran, Iran; and Naveen Ashok Chand, product development manager at Revolution Fibres Ltd., Auckland, New Zealand.

Mary Anne White, Harry Shirreff Professor of Chemical Research (Emerita) at Dalhousie University, Halifax, Canada, has been a member of the group since 2018. She posted this recently:

„Those working on physical property measurements of PCMs might be interested in our recent publication “Thermal Property Determination for Phase Change Materials,” S. Kahwaji, M. B. Johnson and M. A. White, Journal of Chemical Thermodynamics 158, 106439:1-8 (2021). If you would like a reprint, please contact me directly at mawhite@dal.ca.“