THERMAL STORAGE

PCM combined with HDPE for use in 3D printers

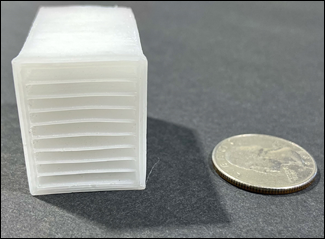

Researchers at Embry-Riddle Aeronautical University have demonstrated that thermal energy storage composites can be printed using a 3D printer and a fused-filament deposition process.

The researchers combined an organic phase change material with high-density polyethylene (HDPE) and extruded the mixture into a functional composite filament that can store heat. The filaments can then be 3D-printed to create heat-exchanging devices. The research is in its early stages, but prototype heat exchangers confirm the potential for use in a wide range of applications. The 3D-printed heat exchanger shown here contains 40 percent PCM in the walls of the HDPE polymer.

The researchers combined an organic phase change material with high-density polyethylene (HDPE) and extruded the mixture into a functional composite filament that can store heat. The filaments can then be 3D-printed to create heat-exchanging devices. The research is in its early stages, but prototype heat exchangers confirm the potential for use in a wide range of applications. The 3D-printed heat exchanger shown here contains 40 percent PCM in the walls of the HDPE polymer.

Sandra Boetcher, professor of mechanical engineering at Embry-Riddle, was a member of the research team. Their work is described in an article published by the journal Additive Manufacturing, “Fused filament fabrication of novel phase-change material functional composites.” Boetcher answered questions about the research by e-mail.

Q: How is the PCM encapsulated inside a composite filament?

A: “We are essentially taking a technology developed about 20 years earlier called ‘shape-stabilizing’ PCM and applying it to additive manufacturing. I got the idea because I was researching how to package PCM. Chemists were doing some research where they would mix PCM with HDPE and extrude it into bricks or injection mold it into bricks. I thought – we can do this with 3D printing…same idea. So we mix PCM and HDPE and extrude it through a filament maker. We use this filament to print heat exchangers.”

Q: What type of PCM is used (salt hydrate, paraffin, biobased) and what is its heat storage capacity in joules per gram?

A: “PureTemp 42; 218 J/g.”

Q: What is the heat storage capacity of the PCM composite filament?

A: “The effective heat capacity of the filament is directly correlated with the amount of PCM in the plastic filament. If we can get 50% PCM in the filament, then the effective latent heat would be 109 J/g. For now, this is about what we are doing. We are trying for 60%. The advantage of being able to 3D print filament is that we can print very thin walls and highly compact heat exchangers with large surface areas and thin walls – if we can get the wall to be thin, we don’t have to worry about trying to add thermal conductivity enhancement since the thermal resistance is equal to thickness/thermal conductivity – we want to reduce thermal resistance so we can do it by decreasing the wall thickness or increasing thermal conductivity. Our method focuses on the former.”

Q: In what everyday applications (on Earth!) do you see this technology being used effectively?

A: “Ha ha, silly aerospace university trying to put an “aerospace” spin on it. The real application is to build PCM heat exchangers to replace ice-based thermal energy storage tanks for load shaving and peak shifting. (Now, we know that PCM 42 is not the correct phase-change temperature for replacing ice storage – we just started with 42 because at first we were working with lithium-ion battery thermal management. So what we are working on now would be doing this with a lower phase-change temperature PCM.”

Q: Is Embry-Riddle pursuing a patent?

A: “Yes, we are pursuing a patent – a provisional patent was filed in December 2020. Of course it takes forever, so it hasn’t been assigned a number yet.”

Q: Is Embry-Riddle pursuing commercialization?

A: “Not yet. It is in very early stages.”

PATENTS

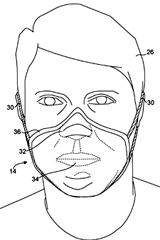

Pathogen-killing filter assemblage

U.S. patent application 20210322802 (applicant KJR Materials Technology Consulting LLC, Rochester, N.Y.:

“A filter configured for capturing and killing pathogens, the filter including a first breathable layer including copper; and a second breathable layer including silver, the second breathable layer coupled to the first breathable layer, wherein the first breathable layer and the second breathable layer cooperate to capture and kill pathogens mobilized through at least one of the first breathable layer and the second breathable layer.”

Multipurpose heat transfer and storage device

U.S. patent application 20210318034 (applicant Sun Buckets Inc., Champaign, Illinois):

“Devices, systems, and methods relating to providing a portable, rechargeable vessel for collecting, storing, and recovering thermal energy are provided. In one aspect, vessel includes a structure defining a well and an open-top portion at the top of the well; a phase-change material, wherein the phase-change material is disposed in the well, the phase-change material being configured to change phase at temperature in the range of 110-700° C.; one or more thermally-conductive fins interleaved in the phase-change material; and a thermally-conductive heat transfer plate disposed at and substantially covering the open-top portion of the structure, in direct thermal contact with the one or more fins, thereby allowing the transfer plate to directly exchange thermal energy with the phase change material.”

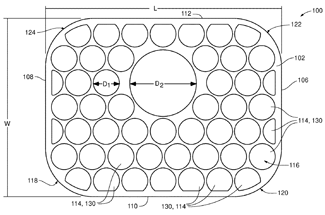

Fertility-enhancing cooling seat

U.S. patent application 20210307959 (inventors David L. Abramson, et al, Englewood, N.J.):

“A fertility-enhancing cooling seat for lowering temperatures of human testicles so as to increase sperm quality and quantity. The cooling seat includes: a top flexible portion and a base portion; a bottom flexible portion coupled to the top flexible portion, the bottom flexible portion forming a seal with the base portion, portions of the bottom flexible portion and portions of the top flexible portion defining isolated cooling cells with cooling-cell volumetric spaces; a phase-change material located in the cooling-cell volumetric spaces, the phase-change material configured to change from a solid phase to a liquid phase at a first temperature and that is configured to change from a liquid phase to a solid phase at a second temperature that is lower than the first temperature. At least one of the isolated cooling cells defines a diameter that is larger than a diameter of the other of the cooling cells.”

Heat exchanger systems and methods

U.S. patent application 20210310706 (applicant Rheem Manufacturing Co., Atlanta, Georgia):

“Disclosed herein are heat exchanger system comprising: a refrigerant; a phase-changing material in thermal communication with the refrigerant; and a valve configured to selectively permit an amount of the refrigerant to flow through the heat exchanger system, the amount of the refrigerant being based on a temperature difference between the refrigerant and the phase-changing material. Also disclosed herein are methods of using the same.”

More U.S. patent applications:

Thermal accumulator containing a PCM (BiofreshTech SL, Valencia, Spain) | Thermal container (va-Q-tec AG, Würzburg, Germany) | Improved battery (Sunamp Ltd., Edinburgh, Scotland) | Battery module (Samsung SDI Co. Ltd., Yongin-si, South Korea) | Cooling system with defrost and temperature rise indicator (King Abdulaziz University, Jeddah, Saudi Arabia) | Internally heated phase change material heat batteries (Sunamp Ltd., Edinburgh, Scotland) | Air conditioning system for vehicle (Hyundai Motor Co. and Kia Motors Corp., Seoul, South Korea) | Method for forming high-efficiency geothermal well bores (Eavor Technologies Inc., Calgary, Canada) | Pallet cover (Cold Chain Technologies LLC, Franklin, Mass.) | Phase change materials for thermal protection in batteries (Toyota Research Institute Inc., Los Altos, Calif.)

IN BRIEF

• A special issue of Energies will be published next year in honor of Luisa F. Cabeza‘s distinguished 25-year scientific career. The theme of the issue, edited by Mohammed Farid, professor of chemical and materials engineering at the University of Auckland, is energy storage with phase change material. The special issue is now open for submissions on such topics as advanced TES materials; novel TES systems and applications; passive and active TES integrated into buildings; integration of TES into smart energy systems and distributed generation; economic and techno-economic analysis of TES systems; and environmental analysis and impact assessment of TES. The deadline for submissions is March 15, 2022.

• The 2021 AD Scientific Index lists Mohammed Farid as New Zealand’s top-ranked scientist in engineering. Using data from Google Scholar, the index ranks the impact of researchers based on the number of publications and the citations that these publications received.

• U.S. textile, flooring and specialty chemical manufacturer Milliken & Co. has acquired Encapsys LLC from the Cypress Performance Group. The transaction officially closed Oct. 18. Terms were not disclosed. Encapsys, based in Appleton, Wis., encapsulates a wide range of material, including perfumes, pharmaceuticals, solvents and phase change material.

• Switzerland’s Lucerne School of Engineering and Architecture has an opening for a research associate and senior research associate scientist. Job responsibilities include assessment of thermal energy systems from building to national scale; characterization and modeling; and data analytics and data-driven modeling.

• Rooftop solar panels are popping up everywhere in cities around the world. Residential wind turbines, on the other hand, are viewed as unsightly and inefficient and are far less common. Designer and entrepreneur Joe Doucet has a solution: a flat wind turbine that can be incorporated into walls. In an interview with Fast Company, Doucet said a turbine wall incorporated into an average American home could meet its yearly energy needs (10,000 kilowatt-hours/year).

• “PCM Masterclass: Using phase change materials to improve thermal packaging,” offered by CAVU Group of Dayton, Ohio, is set for 11 a.m. EST Nov. 10. The 90-minute online class will explain the thermal management uses of PCMs in pharmaceutical and life science packaging and identify new PCM packaging opportunities and applications.

• CAVU Group of Dayton, Ohio, has introduced a PCM-equipped sample tote that protects temperature-sensitive pharmaceuticals and medical devices. The soft-sided “prote-go” tote, shown here, weighs less than 8 pounds and has over 25 liters of payload space.

• Viking Cold Solutions of Houston, Texas, has installed its PCM-based thermal energy storage and refrigeration optimization system in Frigoríficos ARCOSA‘s 64,000-square-foot warehouse in Juquila, Mexico. Viking Cold says the system has shaved peak electricity demand, cut associated carbon emissions and reduced the warehouse’s electric bill by an estimated $120,000 per year.

• Sunamp Ltd. of Edinburgh, Scotland, has published a case study, “Replacing gas boilers in UK high-rise tower blocks.” Sunamp partnered with Kensa Contracting to replace gas boilers with Sunamp’s UniQ heat batteries and Kensa’s Shoebox heat pumps in a 364-apartment complex in Sunderland. The batteries and heat pumps are connected to an open-loop ground-source system. Sunamp says the conversion improves tenant comfort and safety, reduces maintenance costs and cuts carbon emissions by nearly 70 percent a year.

RESEARCH ROUNDUP

From Composites Part B: Engineering:

From Journal of Energy Storage:

• Experimental study on packed-bed thermal energy storage using recycled ceramic as filler materials

From Carbohydrate Polymers:

From Sustainability:

From Renewable Energy and Environmental Sustainability:

From Materials Advances:

From Inventions:

From Building and Environment:

From Energy:

From Surfaces and Interfaces:

• Fabrication of phase change microcapsules and their applications to anti-icing coating

From Construction and Building Materials:

• The effect of phase change materials on cement hydrate in steam-cured cement-based materials

• Study of a novel hollow ceramsite compounded with paraffin phase change materials for energy storage

From Materials Letters:

From Crystals:

• Thermal Energy Storage Materials (TESMs) — What Does It Take to Make Them Fly?

From Materials:

• Review of Solutions for the Use of Phase Change Materials in Geopolymers

From Zeitschrift für Naturforschung A:

• Spherical and cylindrical conductive thermal diodes based on two phase-change materials

From Thermal Science and Engineering Progress:

From International Journal of Energy Research:

From International Journal of Heat and Mass Transfer:

• Development of a new type of PCM thermal capsule transport system

• Natural convection in phase change material: Experimental study

From Applied Thermal Engineering:

From Materials Today: Proceedings:

• Phase change materials for comfort management of poultry farms – A review

From ES3 Web of Conferences:

• A multilayer panel in cork and natural phase change materials: thermal and energy analysis

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,600 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,600 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcomed a surge of new members, including: Jorge Felipe Espeso García, R&D European project manager at Fábrica Española De Confecciones SA, Madrid, Spain; Jorge Felipe Espeso García, senior business development at PTT Global Chemical, Bangkok, Thailand; Mario Reichel, professor of building air conditioning and integrated planning at the West Saxon University of Applied Sciences of Zwickau, Germany; Stefanie Reil, project development at Gammel Engineering GmbH, Abensberg, Germany; Owen Baek, temperature control and protection researcher at S.Lab Asia Inc., Seoul, South Korea; Ken Sears, director of operations at Sonoco, Valparaiso, Indiana; Kim Mak, assistant engineer at GRST, Hong Kong; Jeff Trower, managing director at Carel USA, Huntington Beach, Calif.; Dr. Thomas Maier-Eschenlohr, CEO at Landpack GmbH, Alling, Germany; Nick Baty, principal – building services engineering at Beca, Wellington, New Zealand; Vikas Chauhan, research and teaching assistant at PEC University of Technology, Chandigarh, India; Fabian Fischer, thermal engineer at Modis for Airbus, Immenstaad, Germany; and Andreas Kjällander, head of temperature control management at World Courier, Stockholm, Sweden.

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at info@pcm-ral.de.

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at info@pcm-ral.de.

Axiotherm GmbH | Croda | ISU Chemical Co. Ltd. | RuhrTech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | Sunamp Ltd. | va-Q-tec AG

MEMBER SPOTLIGHT: Croda | East Yorkshire, United Kingdom

As a holder of EcoVadis Platinum status, Croda is a leader in the supply of innovative, sustainable ingredients. Our CrodaTherm™ bio-based phase change materials offer melting points between 5 and 74°C, making them ideal for low-, ambient and high-temperature applications. CrodaTherm PCMs are USDA Certified Biobased and offer high latent heat capacities and sharp melting and freezing points, in addition to high stability for predictable and long-term performance.Learn more at crodaenergytechnologies.com.