NEW PRODUCT

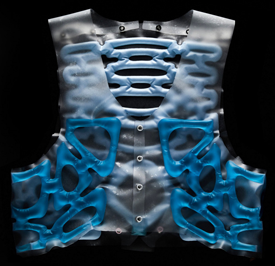

PCM warming vest recharges in boiling water

A London startup that made a splash with “clothes that grow as children grow” has developed a PCM warming vest designed to protect adults from extreme cold.

Petit Pli‘s Entropy Vest uses a salt-based gel that gradually changes from liquid to solid as it warms the wearer. The shell is made of a non-woven vinyl and a tightly woven bonded PES textile. The vest is designed to be worn over a t-shirt or compression top and under a windbreaker or jacket. It can be recharged to its “maximal activation temperature” of 40° C in boiling water.

Petit Pli‘s Entropy Vest uses a salt-based gel that gradually changes from liquid to solid as it warms the wearer. The shell is made of a non-woven vinyl and a tightly woven bonded PES textile. The vest is designed to be worn over a t-shirt or compression top and under a windbreaker or jacket. It can be recharged to its “maximal activation temperature” of 40° C in boiling water.

The vest is available for pre-order on the company’s website. The price: 592.95 euros.

CEO Ryan Mario Yasin, who founded Petit Pli in 2017, made Forbes’ 30 under 30 list of retail and e-commerce innovators in 2020. The company employs a dozen people. Yasin answered questions about the Entropy Vest via e-mail.

Q: How did you become familiar with phase change materials?

A: “Our team make-up consists of a majority of engineers and scientists – PCM materials were definitely in our ether of knowledge. When we began looking into how we, as a team, could add value to the performance of wearables – we naturally thought of PCM materials as a viable and more useful alternative than active electronic components which pose difficulties in durability.”

Q: What inspired the creation of the Entropy Vest?

A: “Rapid and extreme temperature fluctuations are becoming more common – this means extremes of cold, as well as extremes of heat. The initial inspiration began with this signal, we asked ourselves, what if this extreme weather trajectory continues? What if our existing garment solutions are no longer viable in keeping our temperature regulated? Petit Pli’s Entropy Vest is part of our newest mission – to make clothing, and the wearer, adaptable to different weather conditions like never before. Looking at the existing passive solutions on the market showed that there is a lot more yet to be explored in this field.”

Q: Who played key roles in its development?

Q: Who played key roles in its development?

A: “The entire team played key roles in the development of the Entropy Vest. With our interdisciplinary professional backgrounds, we are all able to come together and bring a different perspective to the table, one that will fortify the success of the projects we put our minds to. Notably: Sid Bullmore, Samuel Iliffe, Arabella Turek, Sandy Chen, Fanny Lefebvre-Nare, Guillermo Cardenas and myself.”

Q: How was the development funded?

A: “The initial stages of development have been funded entirely by Petit Pli, using investment and revenue from our existing commercialised solutions. We are now looking for government & commercial partner funding to take the project to the next stage.”

Q: Who supplied the PCM?

A: “We developed the PCM in-house to reach the temperature and consistency we desired for the application of a worn vest.”

Q: Where is the vest manufactured?

A: “For now, the vests are made in small quantities in London, in our own manufacturing facility. Pending results from further user testing and product iterations, we will outsource the production.”

Q: How long does the vest hold usable heat in a given environment (say -15 degrees C)?

A: “The current version has been designed to hold its temperature for a short 1-2 hours. This is in order to design for a particular use-case, a bitingly cold start to a cycling commute home, as the wearer’s body temperature increases with activity, the PCM temperature begins to drop – the aim being to hold a constant body temperature rather than causing the wearer to overheat. This range of use-time also has the benefit of lighter weight and quicker resetting times.”

Q: Have you received inquiries or preorders from large organizations (law enforcement, aerospace, military, etc)?

A: “We are currently unable to specify who has reached out – but the Entropy Vest has certainly gathered a wide range of attention from a variety of large organisations – and we look forward to working with some of those.”

Q: Is Petit Pli developing other PCM-based products?

A: “Certainly, this is just the beginning. The garment industry is one that has lagged behind due to overconsumption and a lack of commercial viability in investing in material R&D, but that is going to change. Petit Pli’s vision is to clothe the future of humanity.”

IN BRIEF

• The trade association Thermal Storage UK has published a report on the potential for “#heatflexibility” by 2030. The association’s founding director, Tom Lowe, writes on LinkedIn: “The report was based on research from the consultants LCP Delta. LCP Delta estimates that the UK could use smart thermal storage in 2.4 million homes to reduce peak #electricity demand on the coldest day of the year by 1.6GW by 2030. This peak demand reduction could increase to 4.1GW if the benefits of flexibility to electricity networks were reflected in pricing. Smart thermal storage can shift 17.64 GWh of electricity across the coldest day.”

• Researchers at Japan’s Shinshu University have developed a fabric woven out of nano-threads with a PCM core, creating a material that can heat up and cool down its wearer depending on ambient temperatures. To address the problem of PCM leakage in PCM-enhanced fabrics, phys.org reports, researchers used a process called coaxial electrospinning, which encapsulates the PCM in the center of the nanofiber to solve the problem of PCM leakage.

• Thermal energy storage expert Luisa Cabeza of the University of Lleida, Spain, has been certified as a European Climate Pact ambassador. Climate ambassadors, selected by the European Commission Directorate-General for Climate Action, “inform, inspire and support climate policy and action in their communities and networks.”

• Norway-based thermal energy storage company Kyoto Group has signed a letter of intent to deploy an 88MWh system in Spain in the second half of 2023. The agreement is with an unnamed company described in a press release as “one of the largest owners of cogeneration facilities in Spain.”

• Earlier this year, Green Building Advisor published a PCM product guide, focusing on products designed to reduce energy use in buildings. It’s a bit of a history lesson combined with an overview of products now on the market, including Phase Change Solution‘s ENRG Blanket; Insolcorp‘s Templok ceiling tiles and roofing systems; Dörken‘s Delta-Cool 24 pouches, balls, panels and sheets; Viking Cold Solutions‘ commercial cold storage panels (shown here); and Sunamp‘s Thermino water heater. Perhaps most interesting is the accompanying discussion, with experts weighing in on the functionality and cost-effectiveness of these products.

• Earlier this year, Green Building Advisor published a PCM product guide, focusing on products designed to reduce energy use in buildings. It’s a bit of a history lesson combined with an overview of products now on the market, including Phase Change Solution‘s ENRG Blanket; Insolcorp‘s Templok ceiling tiles and roofing systems; Dörken‘s Delta-Cool 24 pouches, balls, panels and sheets; Viking Cold Solutions‘ commercial cold storage panels (shown here); and Sunamp‘s Thermino water heater. Perhaps most interesting is the accompanying discussion, with experts weighing in on the functionality and cost-effectiveness of these products.

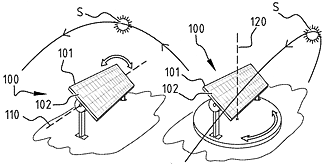

• Vast Solar of Australia is part of a consortium that will receive $2.3 million (US) from the U.S. Department of Energy to develop and test designs of molten salt thermal energy storage tanks to improve the performance of concentrating solar-thermal power technologies in industrial settings. Vast Solar has been operating a 1 MW CSP pilot plant at Jemalong, New South Wales, since 2018. The consortium is led by U.S.-based renewable technology company Solar Dynamics.

• SINTEF Energy Research of Norway offers a look at the PCM-based thermal storage system developed at the ZEB Laboratory, owned and operated by SINTEF and the Norwegian University of Science and Technology in Trondheim. The system uses a biobased PCM with a peak melt point of 37 degrees C to store wind-, waste- and solar-generated thermal energy to warm the lab building. The 200 kWh system, installed more than a year ago, contains 3 tons of PCM. “The PCM-based heat storage system is delivering exactly the performance we expected,” says Alexis Sevault, a research manager at SINTEF. “We’re utilising as much as possible of the building’s self-produced solar energy. We’re also finding that the system is very well suited to so-called ‘peak shaving.’ ”

PATENTS

Roasting system

U.S. patent application 20220322722 (applicant La Bomba SPRL, Hamme-Mille, Belgium):

“A system for roasting particulate material, such as coffee or cacao beans, grains, malt, said system comprising: a photovoltaic unit configured for generating electricity from the solar radiation; a heat storage device comprising at least one phase change material; a roasting device configured for roasting said particulate material; a thermal circuit connecting the heat storage device to the roasting device, and configured for circulating a fluid through the roasting device; and an electrical circuit connecting the photovoltaic unit to the heat storage device, and configured for exchanging heat with said at least one phase change material.”

Composite PCMs with active supporting media for TES applications

U.S. patent application 20220315822 (applicant CIC energiGUNE, Miñano, Spain):

“A composite phase-change material (PCM) has a non-polymeric solid-solid PCM and a solid-liquid PCM. The solid-liquid PCM occupies an internal volume of the solid-solid PCM. The composite material takes full advantage of the latent heat of both PCMs, while avoiding seepage of the inner solid-liquid PCM. A method is for the preparation of the composite PCM. A thermal energy storage device includes the composite PCM.”

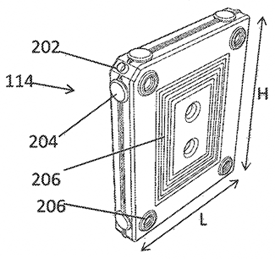

Thermal energy storage array

U.S. patent application 20220316810 (applicant Nostromo Ltd., Even-Yehuda, Israel):

“A thermal energy storage unit is disclosed. The system comprising: a tube having at least one inlet and at least one outlet for a first fluid; a plurality of plate-shaped or box-shaped capsules having a second fluid therein, wherein the plurality of capsules is arranged inside the tube to form a plurality of stacks of capsules; wherein: the first fluid is a heat transfer fluid for exchanging heat with the second fluid; the second fluid is a phase-change medium; wherein a plurality of defined narrow flow paths for the first fluid is provided between the capsules. The defined flow paths increase the efficiency of the system.”

More U.S. patent applications:

Thermal management in comformable tanks (Third Shore Group LLC, Novi, Michigan) | Heat transfer system and method (Mitsubishi Electric Corp., Tokyo) | ThermaSat solar propulsion system (ThermaSat Inc., Scottsdale, Arizona) | Autonomously activable redundant cooling of a heat generating component (OVH, Roubaix, France) | Controllable phase change material bag (South China University of Technology, Guangzhou, China) | Composite container (Proprietect LP and Rapid Air Corp., Canada) | Providing single servings of cooled foods and drinks (ColdSnap Corp., Billerica, Massachusetts) | Devices and methods for high-stability supercooling of aqueous media and biological matter (The Regents of the University of California, Oakland, California)

RESEARCH ROUNDUP

From Journal of Energy Storage:

• Impact of placement and design of phase change materials in thermally activated buildings

• Research progress on the influence of nano-additives on phase change materials

• Development of a novel composite phase change material based paints and mortar for energy storage applications in buildings

• Synthesis and comparative analysis of biochar based form-stable phase change materials for thermal management of buildings

Author links open overlay panel

From Construction and Building Materials:

From Energy Storage Systems:

From Forests:

• Review on the Phase Change Materials in Wood for Thermal Regulative Wood-Based Products [pdf]

From Recent Trends in Product Design and Intelligent Manufacturing Systems:

• Experimental Investigation to Enhance the Performance of Freezer with Phase Change Material

From Journal of Thermal Science and Engineering Applications:

From Energy Reports:

• Experimental study on preparation and thermal storage properties of expanded graphite/paraffin wax as a shape-stabilized phase change material

• A review of heat transfer performance enhancement and applications of inorganic salt based shape-stabilized composite phase change materials for medium and high temperature thermal energy storage

From Industrial & Engineering Chemistry Research:

From Energy and Buildings:

From International Conference on Electrical Machines:

• Measurements on Thermal Buffering of Electric Machine Peak Loads With Phase Change Materials

From International Journal of Biological Macromolecules:

From Applied Thermal Engineering:

• Self-healed inorganic phase change materials for thermal energy harvesting and management

• Effects of shape-stabilized phase change materials in cementitious composites on thermal-mechanical properties and economic benefits

From Fluid Dynamics and Materials Processing:

• Performance of a Phase Change Material Battery in a Transparent Building

From Energy Storage Materials and Devices:

• A novel composite phase change material with cold storage and insulation and its application

From Energy Conversion and Management:

From Applied Polymer Materials:

• Sunlight-Triggered Phase Change Energy Storage Composite Materials for Human Body Thermal Management

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,750 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,750 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Jon Vilasau Sarobe, product development manager at Croda International Plc., Barcelona, Spain; Nico Bousma, technical product manager at Royal Boon Edam International B.V., Amsterdam, Netherlands; Scott Allen, product development scientist, Los Angeles, Calif.; Prakhar Dixit, research scholar at Indian Institute of Technology, Roorkee, India; Pradeep Singh, assistant tech manager at PLUSS Advanced Technologies, Gurugram, India; and Stephan Höhlein, systems engineer at ait-deutschland GmbH., Bayreuth, Germany.

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

Axiotherm GmbH | Croda International Plc. | ISU Chemical Co. Ltd. | RuhrTech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | S.Lab Asia Inc. | Sunamp Ltd. | va-Q-tec AG