HVAC

Belgian startup testing a variety of PCMs for use in its heat battery

A Belgian startup is developing a PCM heat battery designed to pair with heat pumps to store thermal energy for later use in homes and commercial buildings.

Destore SRL, based in Wallonia, was founded in March 2022 by three university friends who set out to transform Belgium’s heating sector, which accounts for more than half of the country’s energy consumption.

Destore SRL, based in Wallonia, was founded in March 2022 by three university friends who set out to transform Belgium’s heating sector, which accounts for more than half of the country’s energy consumption.

Achille Mathot, Destore’s first employee, is head of product development. He answered questions about the company by email.

Q: What is the origin of Destore?

A: “Destore was founded on March 22, 2022. The journey began with Arnaud Latiers, Grégory Meys and Pierre Baijot. The three entrepreneurs recognized the urgent need for decarbonizing Belgium’s heating sector.

“Seeking solutions for this challenge, they consulted Professor Hervé Jeanmart, an expert in thermodynamics and energy at Polytech UCLouvain. His insights on heating networks and heat storage inspired them to establish several companies with a unified vision: to make heating 100% renewable in Belgium. This initiative led to the creation of Karno, Resolia and Destore, with Destore focusing on research and heat storage. While initially targeting the residential sector, Destore maintains a long-term vision of becoming the premier heat storage provider across all sectors.”

Q: How does the battery work?

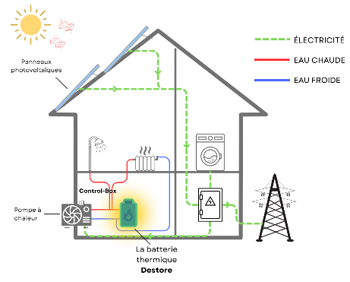

A: “It stores energy in the form of heat. When the heat pump produces hot water, our custom-designed heat exchangers transfer this heat to phase change materials. These materials absorb the heat by changing phase, transitioning from solid to liquid. Subsequently, they release heat when transitioning back to solid, thus heating cold water in the same heat exchangers. PCMs undergo phase transitions at specific temperatures, enabling them to store and release heat effectively for both space heating and domestic hot water purposes. Unlike conventional water tanks, our battery’s temperature remains stable during heating, as the material undergoes a phase change, utilizing latent heat rather than sensible heat. This characteristic makes our product highly compatible with heat pumps, as lower operating temperatures optimize its performance.

A: “It stores energy in the form of heat. When the heat pump produces hot water, our custom-designed heat exchangers transfer this heat to phase change materials. These materials absorb the heat by changing phase, transitioning from solid to liquid. Subsequently, they release heat when transitioning back to solid, thus heating cold water in the same heat exchangers. PCMs undergo phase transitions at specific temperatures, enabling them to store and release heat effectively for both space heating and domestic hot water purposes. Unlike conventional water tanks, our battery’s temperature remains stable during heating, as the material undergoes a phase change, utilizing latent heat rather than sensible heat. This characteristic makes our product highly compatible with heat pumps, as lower operating temperatures optimize its performance.

“The battery is integrated with our intelligent heat pump controller to optimize energy production and storage for maximum financial benefits. Our algorithms consider various dynamic factors, including weather forecasts, the fluctuating electricity production and consumption within the household, and energy prices. The controller adjusts the heat pump operation to store excess energy from photovoltaic solar panels and thus maximize self-generation and self-consumption rates, reduce energy bills and offer flexibility services to grid operators.

“Crafted with a modular and environmentally conscious design, our battery incorporates recycled electronics, thanks to a partnership with a Belgian startup. We prioritize the use of recycled materials during fabrication and ensure that the product is fully recyclable at the end of its lifespan. Our goal is to deliver a product that is highly repairable, easy to maintain and built to endure for over 35 years.”

Q: What type of phase change material will be used?

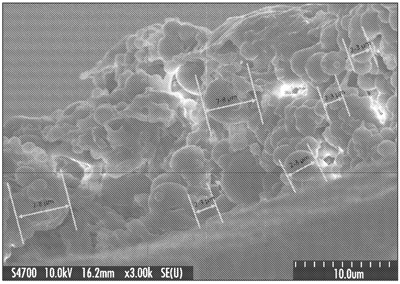

A: “We have been testing various types of PCMs across different temperature ranges, including hydrated salts, paraffins and biobased materials. These PCMs are tested in different formats such as macro-encapsulated in various shapes and materials, raw and micro-encapsulated. Additionally, they are paired with different types of

heat exchangers including fins, metallic foams, tubular and tank designs.

“Our evaluations have determined the performance dominance of each type of PCM within their respective temperature ranges and applications, whether for space heating or domestic hot water. Currently, we are conducting an environmental life cycle assessment of each prototype to understand the true environmental footprint of production compared to a standard water tank without phase change materials.

“Regarding heat capacity, the PCMs in consideration typically range between 180 and 265 j/g or 175 and 322 j/l. The containers are constructed from aluminum, stainless steel, specific injection plastics, and protective layers comprising a mix of epoxy and a hydrophilic solution.”

Q: What factors will determine which PCMs you choose?

Q: What factors will determine which PCMs you choose?

A: The essence of Destore is to use existing materials and assemble them in the best environment possible to provide a high-performance, economical and ecological product. We do not want to enter into the design of a custom PCM at first. This can become a trajectory to take in the event of specific partnership for other projects. Currently tested PCMs come from all around the world (India, Germany, Netherlands, France, China, USA). Determining the most environmentally friendly logistics for PCM sourcing can be complex, as it often involves weighing the energy-intensive manufacturing processes against transportation distances and modes of transportation.

This being said, we collaborate with PCM providers to encapsulate their product in cells, a potential game-changer for heat batteries. This approach allows the minimal components to become a standard, per comparison to AA batteries in electricity storage.”

Q: How are the battery and heat pump connected?

A: “The two devices are connected using the pipe type that the installers prefer. Our device is made to be modular and easy to use for any connections. The transfer fluid is just the water from the heating circuit of the house, no additives are needed. The battery has an entry for the heat pump’s production and a return. They can be bypassed so that the heat pump can directly access the house circuits. And on the other hand, the battery is plugged into the heating circuit and has a safe delivery pipe for the domestic hot water.”

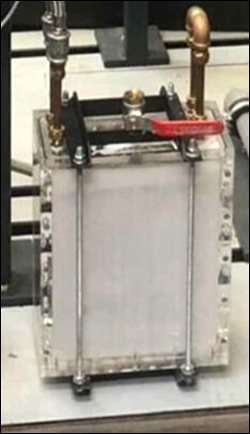

Q: How much PCM will be used in the 9kWh domestic unit shown here (www.destore.energy/en/stocker-ma-chaleur)?

A: “This unit is intended for space heating. Another block will be available for non-integrated heat pumps, which would benefit from both domestic hot water and space heating storage. It will be seamlessly integrated into the existing unit, much like Lego pieces fitting together. The amount of PCM used in this unit will vary depending on the final choice of materials. However, as a general estimate, you can expect around 14 kg of PCM per

kWh.”

Q: Do you plan to offer the thermal battery in other sizes?

A: “Absolutely, we do have plans to offer the thermal battery in various sizes suitable for apartment blocks, commercial buildings, and factories. Our goal is to create a highly modular product where the stored energy quantity can be customized to meet specific needs, measured in kilowatt-hours (kWh). To achieve this, we’re developing what we like to call the ‘AA battery’ of thermal batteries, or cells. These cells consist primarily of PCM, along with a heat exchanger and encapsulation featuring inlets and outlets.

“These cells will be available in both our products for individual consumers and as components of larger units for business clients. By leveraging phase change materials, we can offer flexible designs beyond traditional cylindrical units using water. This versatility allows us to create innovative solutions, such as plates for walls and other unique designs, which is particularly beneficial in multi-residential settings.”

Q: Your crowdfunding effort on ulele.com has raised 11,000 euros, about a thousand more than your goal. What are your other funding sources?

A: “The primary objective of the crowdfunding campaign was to initiate our market approach, assess our branding strategy, and deploy a few smart heat pump controllers in test houses to showcase their effectiveness in reducing energy bills. We have received partial funding from the Walloon Region, in collaboration with universities, research centers, and industrial partners, with a total project budget of 4.3 million euros. However, at this stage, we are unable to utilize the funding from the Walloon Region to conduct prototype testing in real-world conditions. The crowdfunding campaign was instrumental in accelerating our path to market entry and validating our early solutions. Thanks to people’s support, we are ready to deliver a dozen heat pump controllers equipped with our current algorithms. Additionally, we have secured a pre-order for our first heat battery, scheduled for delivery in 2026.”

Q: What excites you about this project?

A: “What excites us most is the incredible range of product possibilities that need to be refined into specific offerings to meet market demands. From residential homes to thermal networks, the technologies involved are similar yet diverse in terms of operations and manufacturing approaches. We are deeply committed to offering solutions only where they are truly needed. We are also thrilled about the partnerships we have yet to forge, as they hold the potential for groundbreaking propositions in the market. We view competitors not as adversaries, but as potential collaborators in shaping new standards within the heating sector.”

IN BRIEF

• Some of the 24-volt lithium-ion batteries used in the Flex line of power tools undergoing tests at Consumer Reports began leaking an “inklike black fluid” after the tests were complete. You can probably guess what it was.

• Some of the 24-volt lithium-ion batteries used in the Flex line of power tools undergoing tests at Consumer Reports began leaking an “inklike black fluid” after the tests were complete. You can probably guess what it was.

• The 18th UK National Heat Transfer Conference will be held Sept. 9-11 at the University of Birmingham. Topics include single phase heat transfer, energy storage, heat exchangers and nature-inspired solutions of flow and heat transfer. The early registration deadline is May 1.

• Outlast Technologies’ new temperature-regulating bedding fabric, Chromo, features “integrated functional capsules” filled with rapeseed oil.

• “Electric heat pumps have been driving fossil fuels out of buildings and homes as electricity replaces oil and gas for heating, cooling, water heating, and drying laundry, too,” writes CleanTechnica’s Tina Casey. “That is just the tip of the electrification iceberg. Hard-to-decarbonize industries are next in line for a clean energy makeover, and the US Department of Energy is on it.”

• In a LinkedIn post, Rubitherm Technologies writes: “Our air-guided PCM storage ‘#PhaseCube’ with our #certified PCM ‘SP21EK’ has been tested for more than 100 cycles till now in our test rig. A volume flow rate of 200 m3/h was selected for testing as a widely used value according to our #customers. Additionally, measurements with lower volume flow rates were also conducted to determine power and capacity in more detail.” Rubitherm will exhibit the PhaseCube cooling system at Salon Passibat’, the French fair for zero-energy housing solutions, March 26-27.

• An update from the European Horizon project BIOBUILD on LinkedIn: “One of the innovative strategies is incorporating bio-phased change materials (bioPCMs) into solid #wood. BIOBUILD is working with Europe’s largest flooring producer Pervanovo Invest and the largest manufacturer of particle boards in #Sweden Byggelit Sverige AB to demonstrate the impregnated flooring and wallboards with bioPCM, enabling maximum energy performance with minimal impact on the #environment.”

• Sunamp Ltd. CEO Andrew Bissell, right, has been named to the United Kingdom’s new small business council, which met for the first time this month at Downing Street.

• Sunamp Ltd. CEO Andrew Bissell, right, has been named to the United Kingdom’s new small business council, which met for the first time this month at Downing Street.

• The new MolCal consortium is seeking applicants for 10 doctoral candidate positions. The research will focus on magneto-, baro-, mechano- and electro-caloric materials. The application deadline is April 21. Sunamp Ltd. is partnering with the University of Edinburgh to examine a barocaloric material that changes phase when put under pressure and cools strongly.

• Va-Q-Tec AG, Würzburg, Germany, says its new va-Q-gel thermal coat significantly improves the performance of conventional thermal covers used to protect temperature-sensitive shipments.

PATENTS

Thermal management system with phase change and auxiliary cooling systems

U.S. patent 11,889,664 (applicant Baidu USA LLC, Sunnyvale, Calif.):

“A thermal management system includes a cooling unit, a condenser, and a processor. The processor is located within a server, and the system also includes a phase change cooling device in thermal communication with the processor, and in fluid communication with the condenser. The system also includes a single phase cooling device in thermal communication with the phase change cooling device, and in fluid communication with the liquid cooling unit. The system also includes a temperature sensor in thermal communication with the single phase cooling device, and a fluid pump to move fluid between the liquid cooling unit and the single phase cooling device. A TEC device may also be implemented between the phase change cooling device and the single phase cooling device.”

Triple network cooling hydrogel

U.S. patent application 20240043729 (applicant Honeywell International Inc., Charlotte, N.C.):

U.S. patent application 20240043729 (applicant Honeywell International Inc., Charlotte, N.C.):

“The invention provides triple crosslinked cooling hydrogel compositions of high tensile strength, high compressibility, high elasticity, and long cooling period and methods of making the compositions. The compositions are useful in clothing and equipment for wear in high solar radiation environments and high temperature environments.”

Metal nitrate based compositions for use as phase change materials

U.S. patent 11,891,561 (applicant Sunamp Ltd., East Lothian, Great Britain):

“There is disclosed herein metal nitrate hydrates as phase change materials (PCMs). More particularly, there is disclosed herein metal nitrate hydrate PCMs containing group II metal nitrates as nucleation agents. A further disclosure herein is the combination of multiple chemical species in the PCM formulation which act together to induce nucleation of metal nitrate PCMs. Furthermore, physical mechanisms by which nucleation of metal nitrate hydrate based PCMs and crystallisation rate increased are disclosed.”

More U.S. patents and applications:

Latent heat storage material and cold storage tool (Sharp Kabushiki Kaisha, Sakai, Japan) | Thermal energy storage system with phase change material (Henrik Stiesdal, Odense, Denmark) | Hybrid systems and methods for managing thermal energy (Phasestor LLC, Charlotte, N.C.) | Process and system for hydrotreating renewable feedstock

(Green Technology Research Co. Ltd., Bangkok, Thailand) | Article of footwear with cooling features (Under Armour Inc., Baltimore, Maryland) | Temperature treatment apparatus (Bandicool Pty. Ltd., Middle Park, Australia) | Mobile energy storage internet system (Nanjing Tech University, Nanjing, China) | System for heat exchange between a building and the earth’s subsoil (IFP Energies nouvelles, Rueil-Malmaison, France) | Active thermal transportation system (Cody Johnson, Nashville, Tennessee; and Kenneth Lowrence, Schaumburg, Illinois)

RESEARCH ROUNDUP

From Journal of Energy Storage:

• Evaluation of the thermal properties of subzero phase-change materials by the T history method during the solidification and melting phase

• Optimal sizing of electrical and thermal energy storage systems for application in fuel cell based electric vehicles

• Thermal energy storage for direct steam generation concentrating solar power plants: Concept and materials selection

From Materials Today Sustainability:

• Shape stable composite phase change material with improved thermal conductivity for electrical-to-thermal energy conversion and storage

• High value utilization of waste peanut shell: Prepared novel shape stable composite phase change materials with high thermal conductivity

From Journal of Building Engineering:

From Energy:

• Experimental study of breathable and heterogeneous phase change material (B&H-PCM) wall for all-season thermal performance enhancement

• Golf-ball-inspired phase change material capsule: Experimental and numerical simulation analysis of flow characteristics and thermal performance

From Applied Thermal Engineering:

From Applied Energy:

• Evaluation of phase change thermal storage in a cascade heat pump

• A hybrid battery thermal management system using ionic wind and phase change material

• Field experiment testing of a low-cost model predictive controller (MPC) for building heating systems and analysis of phase change material (PCM) integration

From Micro:

From Polymers:

• Bio-Based Polymers for Environmentally Friendly Phase Change Materials

From ASME Journal of Heat and Mass Transfer:

From Frontiers:

From Next Materials:

• Renewable wood-phase change material composites for passive temperature regulation of buildings

From Energies:

• Molten Salts Tanks Thermal Energy Storage: Aspects to Consider during Design

From Construction and Building Materials:

From International Journal of Biological Macromolecules:

From Open Engineering:

From Energy Conversion and Management:

• Solar-powered hybrid energy storage system with phase change materials

From Sustainable Energy Technologies and Assessments:

From International Journal of Refrigeration:

From AIP Conference Proceedings:

• Study of coconut oil and expanded graphite mixture as phase change material

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,800 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,800 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Xiong Teng, a researcher at Chinese Academy of Sciences, Guangzhou, China; Soumalya Mukherjee, co-founder at Tan90, Chennai, India; Alessandro Ribezzo, Ph.D. student at Polytechnic University of Turin, Italy; and An Zhao, a research associate at Delft University of Technology, Netherlands.

A recent post from member Mar Alonso Martínez:

“Happy to share our #OpenAccess contribution about #numerical #modeling of Macroencapsulated PCM using the Effective Heat Capacity Method. A great work which is the next step in our challenge to design innovative #AdaptiveEnvelopes for buildings!! Dealing with #climatechange, improving energy efficiency of buildings is needed. This model will help to simulate macroencapsulated PCMs and their singular thermal performance as solid material with low computational cost. It is an efficient model to be integrated in building energy simulation. Because #PCMs are coming to the #building sector, #researchers have to provide tools to analyze them! If you want to know more details do not hesitate to contact us.”

“Happy to share our #OpenAccess contribution about #numerical #modeling of Macroencapsulated PCM using the Effective Heat Capacity Method. A great work which is the next step in our challenge to design innovative #AdaptiveEnvelopes for buildings!! Dealing with #climatechange, improving energy efficiency of buildings is needed. This model will help to simulate macroencapsulated PCMs and their singular thermal performance as solid material with low computational cost. It is an efficient model to be integrated in building energy simulation. Because #PCMs are coming to the #building sector, #researchers have to provide tools to analyze them! If you want to know more details do not hesitate to contact us.”

Harald Mehling, another group member, has published a paper titled “Development of a Consistent Understanding of Energy, Energy Conservation, and Derivation of a Systematic Set of Energy.”

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

Axiotherm GmbH | B Medical Systems | Croda International Plc. | ISU Chemical Co. Ltd. | RuhrTech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | S.Lab Asia Inc. | Sunamp Ltd. | va-Q-tec AG