HVAC

Swiss startup using prize money to develop novel TES prototype

SeasonCell, the Swiss startup that is developing a PCM-based seasonal energy storage system for houses, took second place in the LUKB Future Prize competition last month. The award is worth 50,000 Swiss francs (about $57,000) provided by contest sponsor Luzerner Kantonalbank.

SeasonCell will use the money to develop a prototype of the system, which stores excess energy in summer and then releases it, in the form of heat, in winter. Switzerland generates a surplus of electricity in summer, thanks to its hydroelectric dams and solar voltaic installations.

The system uses sodium acetate trihydrate (used typically in hand warmers) to store thermal energy. “SAT is a good option,” says co-founder Janis Perren. “But there are other options which may be better for our case.”

The system uses sodium acetate trihydrate (used typically in hand warmers) to store thermal energy. “SAT is a good option,” says co-founder Janis Perren. “But there are other options which may be better for our case.”

The SeasonCell team is composed of five master’s students at the Lucerne University of Applied Sciences and Arts and the Zurich University of Applied Sciences. In an email interview, Perren responded to questions about the project.

Q: How is phase change material used in your system?

A: “The PCM is stored in a tank. In the beginning, the PCM is in a solid state (and at ambient temperature). In warm summer days, when there is too much energy or heat in a building, that energy or heat is being used to melt that SAT (not all at the same time, but part per part). The melting temperature is above the ambient temperature (depends on the chosen PCM).

“The liquid PCM then cools down to ambient temperature and stays there. This is called ‘supercooled’ and is an interesting phenomena. Normally, a material would solidify if the temperature sinks below the melting temperature. A PCM can stay liquid under that melting temperature. So it does not lose any energy over time, because it has the same temperature as the ambient.

“In cold winter months, when heat is needed, the right amount of PCM will be ‘crystallized’ (the same happens as you would click the metal plate in a hand warmer). The PCM gets solid quick and the temperature rises back up to the melting temperature. This hot PCM can then be used to heat up the water in a heating system.”

“In cold winter months, when heat is needed, the right amount of PCM will be ‘crystallized’ (the same happens as you would click the metal plate in a hand warmer). The PCM gets solid quick and the temperature rises back up to the melting temperature. This hot PCM can then be used to heat up the water in a heating system.”

Q: What is the peak melting point of the SAT? What is its energy capacity in joules per gram?

A: SAT has a melting point of 58 degrees C and an energy capacity of 226–260 kJ/kg.

Q: In what material is the SAT contained (aluminum, copper, HDPE)?

A: “I can’t tell you more about that.”

Q: In hand warmers, a metallic disk is used to trigger release of stored energy. What triggers energy release in the SeasonCell system?

A: “I can’t tell you more about that.”

Q: Roughly how much SAT would be needed for a home system?

A: “That depends on a lot of variables, e.g. the coverage rate, energy consumption of the building, heat system etc. But roughly I would say about 28m3.”

Q: Has the technology been tested at lab scale? Is a pilot project in the works?

A: “We already constructed a test bench to verify different parts of a future prototype. And we are starting this summer with the construction of a prototype to heat a single family house. This would then be our pilot project, which first version should be finished in 2024.”

Q: Has there been an “aha!” moment in the development of the technology?

A: “We actually had some of them, in the triggering of the crystallization and the construction of the tank itself.”

Q: Who are your partners in constructing the prototype and what roles are they playing?

A: “Currently we do not have any official partners in the construction of the prototype. You can find all partners on our website, seasoncell.ch. Some of them help us out with material and others with expertise. But the most important partners are the HSLU (where four of our advisors come from and which give us access to a very big area of laboratory space and also employees’ labor) and the ZHAW (where one of our advisors belongs to and helps us out).”

IN BRIEF

• Researchers at Florida’s FAMU-FSU College of Engineering are working to improve the safety and performance of electric vehicles with a new design that protects batteries in two ways. Thin-walled aluminum tubes filled with phase change material not only absorb excess heat and reduce the risk of fire – they can also soften the blow of impact in a crash. “We want to manage the risk of battery damage in a crash,” said Farhad Farzaneh, a doctoral candidate in the Department of Civil and Environmental Engineering and the study’s lead investigator. “This is a significant concern in the overall safety and reliability of electric vehicles and will help advance their adoption in the automotive industry.”

• Pluss Advanced Technologies Ltd., Gurugram, India, is teaming up with the U.K.-based Rodnight Partnership to expand the availability of the Pluss MiraCradle in the Middle East, Africa and Southeast Asia markets. The neonatal cooling device uses phase change material to induce therapeutic hypothermia among newborns suffering from birth asphyxia.

• Pluss Advanced Technologies Ltd., Gurugram, India, is teaming up with the U.K.-based Rodnight Partnership to expand the availability of the Pluss MiraCradle in the Middle East, Africa and Southeast Asia markets. The neonatal cooling device uses phase change material to induce therapeutic hypothermia among newborns suffering from birth asphyxia.

• The INPATH TES network is offering a new lesson titled “Introduction to life cycle assessment (LCA).” Luisa F. Cabeza of the University of Lleida, Spain, writes on LinkedIn: “The lesson provides useful material on life cycle assessment, including methodology, the life cycle inventory, the impact assessment, and a few examples. The lesson is addressed to PhD students and researchers interested in applying LCA in their work.”

• RGEES LLC, Arden, N.C., has launched a new website, pcmpacks.com, to showcase its PCM-based savENRG heating and cooling packs.

• Joachim Kuhn, CEO and founder at va-Q-tec AG, Würzburg, Germany, has been awarded a Rudolf-Diesel-Medaille, Europe’s oldest innovation award, in the category of “most sustainable innovation achievement.”

• Kyoto Group AS of Norway reports that it has successfully connected its first full-scale molten salt thermal energy storage system to the grid in northwestern Denmark. The facility, developed under Kyoto’s Heatcube brand, is located at the Nordjylland power station in Aalborg.

• Two hotels in Beverly Hills, Calif., have added Nostromo Energy‘s thermal energy storage system to cut their carbon footprints and reduce cooling costs. Power from the grid will charge the IceBrick system at times when renewable energy levels are high, freezing water into ice. The system will then use the ice in the late afternoon and evening, when electricity demand reaches its highest levels, to cool the buildings. The 1.4 MWh storage system installed in the Beverly Hilton also serves the adjacent Waldorf Astoria Beverly Hills.

• Hongbin “Bill” Ma of the University of Missouri has been presented the Donald Q. Kern Award by the American Society of Mechanical Engineers and the American Institute of Chemical Engineers for his pioneering work in phase change heat transfer processes and oscillating heat pipes.

• Sunamp Ltd. of Edinburgh, Scotland, has posted a case study of a heat-battery installation in a home in New Mexico. Kyrie and Hal Stillman‘s “one-of-kind, energy-independent residence” uses surplus solar energy to charge two 200-liter-equivalent Uniq 9 heat batteries. One unit provides hot water for domestic use; the other supplies in-floor heating at night.

• In a LinkedIn article, Michael Ridler, operations manager at Eden Energy Equipment Ltd., Canada, offers his take on Sunamp’s technology: “I recently had the opportunity to visit a site in Guelph, Ontario, where a thermal storage setup utilising the innovative phase change thermal battery Sunamp was being deployed. … As someone deeply passionate about hydronic heat pump systems, I found myself greatly impressed by the Sunamp technology. It immediately sparked my imagination regarding its potential to revolutionise the design and installation of hydronic heat pump systems.”

• Ron Haub, formerly sales director at Placon Corp. and segment director at Sonoco ThermoSafe, has joined Phase Change Solutions of Asheboro, N.C., as chief revenue officer.

• C-Therm Technologies of Fredericton, New Brunswick, has an opening for a product development manager.

PATENTS

U.S. patent application 20230221081 (applicant French Alternative Energies and Atomic Energy Commission, Paris, France):

U.S. patent application 20230221081 (applicant French Alternative Energies and Atomic Energy Commission, Paris, France):

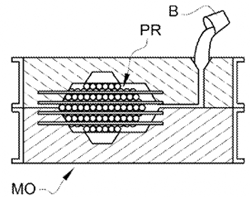

“The invention relates to a modular assembly for storing heat by phase-change material including a plurality of heat-storage modules attached to one another, the heat-storage assembly comprising a vessel. At least two adjacent modules are disposed so that a porous external wall of one of the modules is arranged facing a porous external wall of the other of the modules, and so that a solid external wall (6a) of one of the modules (M1), forming one of the parts of the vessel, is attached to a solid external wall (6a) of the other of the modules (M1), forming another part of the vessel.”

Heat storage composite material

U.S. patent application 20230220260 (applicant AAC Technologies Co. Ltd., Nanjing, China):

“A heat storage composite material comprises components by weight: 30-55 parts of organic phase change material, 30-40 parts of two-dimensional thermally conductive carbon material, 10-20 parts of lamellar structure graphite, and 0-10 parts of oil-absorbing organic resin. A preparing method include steps of stirring the organic phase change material to disperse on a surface of the two-dimensional thermally conductive carbon material, and melting them so the organic phase-change material is adsorbed in gaps of the two-dimensional thermally conductive carbon material; stirring and mixing the lamellar structure graphite and the two-dimensional thermally conductive carbon material adsorbed with the organic phase change material in a mixer to obtain a mixed material; and placing the mixed material in a lamination mold for lamination treatment to obtain a sheet-shaped heat storage composite material. The heat storage composite material has high thermal conductivity and is not easy to leak.”

Phase change material screening

U.S. patent application 20230203359 (applicant Hubbard Products Ltd., Suffolk, England):

U.S. patent application 20230203359 (applicant Hubbard Products Ltd., Suffolk, England):

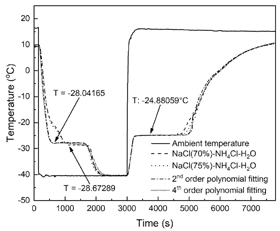

“A method of formulating a ternary salt-water solution having a target phase change temperature – the ternary salt-water solution having a first salt, a second salt and water – includes: identifying at three or more temperatures, a maximum total concentration of the first and second salts in a saturated solution thereof, and the respective concentration of each salt therein, correlating the respective concentration of each salt therein with temperature, predicting a concentration for each of the salts at the target phase change temperature using the correlations, and formulating a ternary salt-water solution with a concentration of the first and second salts based on the predicted concentrations at the target phase change temperature. The method is suitable for phase change material screening, and in particular identifying and optimising phase change materials which can be used as cold storage materials.

”

More U.S. patent applications:

Method of packing a temperature-controlled product (Packaging Technology Group Inc., Fall River, Massachusetts) | Polymeric composition containing a phase change material (Sabanci University, Istanbul, Turkey) | Lithium-ion battery thermal management and method based on phase change material and mutually embedded fins (University of Nottingham Ningbo China, Ningbo City, China) | PCM composition (Agency for Science, Technology and Research (Singapore,, Singapore) | Removable mattress topper with vibrating units (Dreamwell Ltd., Doraville, Georgia) | Battery pack design for phase change management (Baidu USA LLC, Sunnyvale, Calif.) | Battery-operated food thermometer (Vorwerk & Co. Interholding GmbH, Wuppertal, Germany) | Multi-stage variable type waste heat storage and recovery apparatus (Emsolution Co. Ltd., Suwon-si, South Korea)

RESEARCH ROUNDUP

From Journal of Energy Storage:

• A comprehensive review on solar to thermal energy conversion and storage using phase change materials

• A novel phase change material matrix: Study on phase transition behavior of bishexadecyl maleate

From Environmental Science and Pollution Research:

From Materials Today Sustainability:

From Case Studies in Thermal Engineering:

• Technical method in passive cooling for photovoltaic panels using phase change material

From Materials Today: Proceedings:

• Research trends in phase change materials (PCM) for high-performance sustainable construction

From Journal of Fluid Mechanics:

From Journal of Applied Polymer Science:

From Construction and Building Materials:

• Phase change material (PCM) integrations into buildings in hot climates with simulation access for energy performance and thermal comfort: A review

• Investigation on properties of phase change foamed concrete mixed with lauric acid-hexadecanol/fumed silica shape-stabilized composite phase change material

From Energy:

From Journal of Food Engineering:

From Journal of Cleaner Production:

From IEEE International Workshop on Metrology for Living Environment :

• Experimental tests to assess the effects of Phase Change Materials in building envelopes

From International Journal of Engineering Science:

From Journal of Building Engineering:

From Applied Thermal Engineering:

From Applied Magnetic Resonance:

From Applied Energy

From Buildings:

From Renewable and Sustainable Energy Reviews:

From International Journal of Thermal Sciences:

• Metallic wool for enhanced thermal conductivity of phase change materials

From International Journal of Thermal Analysis and Calorimetry:

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,790 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,790 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Vahid Piroozmand, mechanical and energy engineering researcher, Tehran, Iran; Brian Chapman, senior manager in materials science, Biomason Inc., Durham, N.C.; Jason Bennett, general manager at Temprecision International Europe, Newcastle upon Tyne, England; Hou Fong Chang, pursuing master’s engineering degree in building science at British Columbia Institute of Technology, Vancouver, Canada; Mike Teahan, director at Renewable Building Solutions, County Kerry, Ireland; Vijay Kumar, PCM engineer, B Medical Systems India Pvt. Ltd., Mundra, India; Nikhil Sachdeva, lecturer in organic and analytical chemistry, Republic Polytechnic, Singapore; and Sophia Ahmed, Ph.D. student at Texas A&M University, College Station, Texas.

In her first group post, Sophia writes:

In her first group post, Sophia writes:

“I’m a part of a team of graduate students here at Texas A&M University participating in the NSF i-Corps Summer cohort, where we are looking into potentially commercializing aspects of our research into PCMs and their use in thermal energy storage applications. We are looking to interview people in this industry to gain insight into making a product out of our work. If anyone is interested in helping, please message me to set something up.”

In another recent post, PCM researcher Harald Mehling writes:

I am happy that my new paper “Review and Analysis of Existing Approaches to Investigate Property Degradation of Phase Change Materials and Development of a New Systematic Approach” is now published, a paper that I worked on for about a year. It is OpenAccess, and you can find it via ResearchGate https://lnkd.in/e_zck5F6 or directly via the publisher at https://lnkd.in/eDj-TZAm.

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

Axiotherm GmbH | Croda International Plc. | ISU Chemical Co. Ltd. | RuhrTech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | S.Lab Asia Inc. | Sunamp Ltd. | va-Q-tec AG