BUILDING MATERIALS

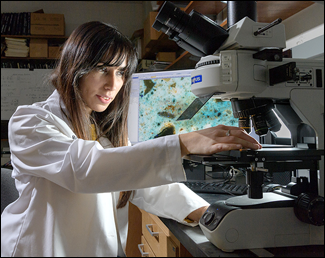

New method embeds PCM in surface of building materials

Researchers at Purdue University have developed a process that embeds PCMs in the surface of construction materials such as bricks, drywall and concrete to enhance their thermal performance.

Researchers at Purdue University have developed a process that embeds PCMs in the surface of construction materials such as bricks, drywall and concrete to enhance their thermal performance.

“Currently, PCMs are incorporated into other materials via microencapsulation or macroencapsulation,” said Mirian Velay-Lizancos, an assistant professor of civil engineering. “However, these methods limit the use of PCMs. Microencapsulation has a negative effect on the strength and durability of construction materials. Macroencapsulation limits the shape and production method of construction materials.”

The new process uses liquid immersion and a vacuum to apply PCMs so that they are concentrated near the surface. Velay-Lizancos says this approach increases the strength and durability of the construction materials, as well as the effectiveness of the PCMs.

The next step for researchers is to build a full-scale prototype. Industry partners seeking to help develop the process should contact Parag Vasekar, psvasekar@pf.org, about reference number 2022-VELA-69766, “Novel Building Envelope Materials with Enhanced Durability That Reduce Energy Consumption.”

IN BRIEF

• Phase Change Solutions, Asheboro, N.C., has added a shape-stable PCM product designed to protect perishable food, pharmaceuticals and biomaterials. The company says the extruded BioPCM Brick is reusable, durable and maintains its shape up to +60⁰ C.

• The European Commission’s proposed Net Zero Industry Act, published in mid-March, includes energy storage as a technology eligible for regulatory support in the European Union. Energy Storage News reports that the categorization includes not just batteries, but all forms of energy storage, including heating and cooling storage technology. The proposed act is a framework of measures designed to boost the manufacture of net-zero technology products in Europe.

• Thermal battery company Sunamp Ltd. has signed an agreement with Sheen Parkside to work together to establish mobile heat networks across the United Kingdom. The networks will use Sunamp’s Plentigrade phase change material technology in shipping-container-size thermal batteries. Sheen Parkside and Sunamp will initially work with waste-to-energy plants, whose spare heat will be used to charge Sunamp’s thermal batteries. The charged batteries will be transported to district heating networks by electric vehicles, rail or barge.

• BioLife Solutions Inc., Bothell, Washington, announced the launch of Ultraguard phase change material, a “non-toxic, non-hazardous and non-flammable” -70° C PCM. The company described the product as a potentially disruptive alternative to dry ice for storing and shipping biologic materials that require ultra-low temperature protection. The PCM is stored in a plastic bottle or “brick” that is charged to a solid state by freezing below -80° C. A color change indicates when the PCM is fully charged.

• BioLife Solutions Inc., Bothell, Washington, announced the launch of Ultraguard phase change material, a “non-toxic, non-hazardous and non-flammable” -70° C PCM. The company described the product as a potentially disruptive alternative to dry ice for storing and shipping biologic materials that require ultra-low temperature protection. The PCM is stored in a plastic bottle or “brick” that is charged to a solid state by freezing below -80° C. A color change indicates when the PCM is fully charged.

• Financier Worldwide Magazine goes deep on the energy-related incentives of the U.S. Inflation Reduction Act in a special report titled “Financing standalone battery storage: the Inflation Reduction Act unlocks the tax equity investor.”

• Zentek Clothing, Lake Stevens, Washington, has launched a line of boot insole products that use phase change material to maintain thermal comfort in extremely cold conditions.

AWARDS

• Monodraught Ltd.‘s hybrid ventilation with heat recovery system, HVR Zero, won the air quality product of the year award in the annual competition organized by the Chartered Institution of Building Services Engineers, London.

• A PCM heat storage device designed to control Varroa mites in beehives won the wild card prize in this year’s Collaborate to Innovate Awards. BeeSave, developed at the University of Nottingham, England, kills mites by exposing them to temperatures between 40° C to 47° C for 150 minutes. Honeybees are not affected by such temperatures.

JOBS

• The University of Twente, Enschede, Netherlands, is seeking candidates for the position of assistant professor in heat conversion and storage. The job will focus on “experimental techniques in sustainable heat processes including the storage, conversion and transfer of heat, with applications in heat management of devices, industrial waste heat recovery, and evaluation of materials for energy storage and conversion.” The application deadline is May 1, 2023.

• The International Energy Research Center, Cork, Ireland, is seeking candidates for the position of postdoctoral researcher – building scientist. Requirements include experience in building thermal simulation including design of HVAC systems, design of new building components for energy or daylighting improvement, and the use of leading simulation packages such as EnergyPlus, TRNSYS and Dymola.

• The Global Energy Interconnection Research Institute, Berlin, Germany, is seeking a thermal energy storage research engineer. The successful candidate will take a leading role in the research and development of energy storage systems. Requirements include a master’s degree in engineering thermal physics, process engineering, chemical engineering or a comparable qualification. Fluency in English and Chinese is essential.

• The University of Nottingham, Nottingham, England, is seeking candidates for a research associate/fellow in research and development of domestic thermal energy storage: advanced distributed storage for grid benefits. Candidates should have experience in energy systems performance monitoring, data acquisition and data handling. The application deadline is April 14, 2023.

• Michaels Energy, La Crosse, Wisconsin, is seeking a thermal energy consulting engineering lead to assist with the launch of a thermal energy consulting service. Requirements include a bachelor’s degree in mechanical engineering or a related field and seven years of experience in HVAC, refrigeration and energy efficiency.

• The National Renewable Energy Laboratory, Golden, Colorado, is offering a summer internship in thermal energy storage. Candidates must be enrolled as a full-time student in a bachelor’s, master’s or Ph.D. degree program, or have graduated in the past 12 months. Qualifications include understanding of thermal systems and heat transfer and proficiency in the C++, Matlab or Python coding and languages and scripts.

PATENTS

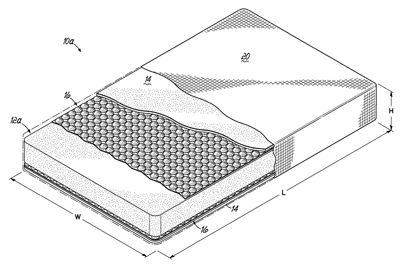

Comfort layer with liquid pods

U.S. patent application 20230092044 (applicant L&P Property Management Co., South Gate, Calif.):

“A comfort layer for a bedding or seating product has liquid pods sandwiched between plies of fabric. The plies of fabric are joined with seams thereby creating pockets, at least one liquid pod being inside each pocket. Each seam joining opposed plies of fabric around each of the liquid pods of the comfort layer may be segmented or solid, depending upon the fabric and type of seam.”

Bottle type cooling pack

U.S. patent application 20230087536 (applicant FMS-Korea Co. Ltd., Hwaseong-si, Korea):

“The present invention provides a bottle type cooling pack including a case, which: has a storage space formed therein to store a refrigerant including a phase change material (PCM), the phase of which varies according to temperature; has a front surface and a rear surface, the widths of which are wider than that of a side surface thereof; and has a rectangular hexahedral shape formed through the front surface and rear surface and curved in the forward and backward directions.”

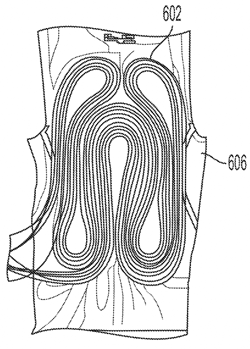

Personal thermoregulation backpack

U.S. patent application 20230051351 (applicant Oceanit Laboratories Inc., Honolulu, Hawaii):

“Disclosed herein are thermally conductive materials, including, for instance, thermally conductive tubing, thermally conductive devices and/or systems (e.g., apparel, backpacks, and the like), and applications thereof. In at least one embodiment, a thermally conductive material is disclosed that is made from one or more base polymers and one or more additives that increase the thermal conductivity of the thermally conductive material relative to the one or more base polymers. In additional embodiments, a cooling vest and a cooling backpack are disclosed, both of which are wearable by human users to keep their body temperature below a certain value. The vest and/or the backpack may include tubing through which coolant flows. The tubing is placed within the fabric and is arranged so that it contacts the user’s skin.”

Density controlled PCM spheres

U.S. patent application 20230082570 (applicant UT-Battelle LLC, Oak Ridge, Tennessee):

“A medium for energy storage includes a plurality of capsules. Each capsule contains a phase changing material (PCM) configured to undergo a liquid-solid phase transition at a solidification temperature, TS. The PCM undergoes a relative volume change due to the phase transition. A shell is filled with the PCM. The shell contains a first heat-conducting material, and is configured to comply to the relative volume change.”

More U.S. patent applications:

Incubator for enrichment during transport (Institute for Environmental Health Inc., Lake Forest Park, Washington) | Temperature protective package with shape-conforming PCM (Edwards Lifesciences Corp., Irvine, California) | Composite energetic material with self-regulated temperature (Trustees of the University of Pennsylvania, Philadelphia) | Degradable delivery particles based from amine containing natural materials (Encapsys LLC, Appleton, Wisconsin) | Wearable garment (Aryam Ahmad and Latifa Omar Alseiari, Abu Dhabi, United Arab Emirates) | Thermal control of powered systems on-board a flight vehicle (Raytheon Co., Waltham, Massachusetts) | Heating system (Intellihot Inc., Galesburg, Illinois) | Temperature control sheets for packaging (Phase Change Solutions Inc., Asheboro, N.C.)

RESEARCH ROUNDUP

From Applied Sciences:

• Use of Phase Change Materials for Food Applications—State of the Art in 2022

From International Journal of Thermofluids:

From Materials Today: Proceedings:

• Comparison Study Of GRA, COPRAS And MOORA For Ranking Of Phase Change Material For Cooling System

From Energy, Ecology and Environment:

• Indoor thermal management of a public transport with phase change material (PCM)

From RSC Advances:

From Wood Material Science & Engineering:

From Journal of Polymer Engineering:

From Fire Science and Technology:

From Journal of Building Engineering:

From Journal of Energy Storage:

• Development of palmitic acid-lauryl alcohol as binary eutectic for cold thermal energy storage in buildings indoor thermal comfort application – Thermophysical studies and discharging characteristics

• Integration of recycled waste paper with phase change material in building enclosure

• A novel numerical approach for measuring phase change temperature range of Phase Change Material in real building conditions

From Sustainability:

From Chemical Engineering Journal:

From Energy:

• A novel hydrated salt-based phase change material for medium- and low-thermal energy storage

From Energies:

• Small-Scale Phase Change Materials in Low-Temperature Applications: A Review

• A Review of the Performance Improvement Methods of Phase Change Materials: Application for the Heat Pump Heating System

From Thermochimica Acta:

From Forests:

• Phase-Change-Material-Impregnated Wood for Potential Energy-Saving Building Materials

From Chemical Thermodynamics and Thermal Analysis:

From ACS Applied Materials & Interfaces:

From Building and Environment:

• Retrofitting buildings with phase change materials (PCM) – The effects of PCM location and climatic condition

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,750 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,750 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Mathew George, assistant professor and researcher at Atria University, Bengaluru, India; Roheet Raajeshwari, materials manager, Seattle, Wash.; Calvin Chew, sales and marketing at KLK Oleo, Shah Alam, Malaysia; Geoffrey Roy, research associate at Catholic University of Louvain, Brussels, Belgium; and Jakub Curpek, assistant professor at Slovak Academy of Sciences, Bratislava, Slovakia.

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

Axiotherm GmbH | Croda International Plc. | ISU Chemical Co. Ltd. | RuhrTech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | S.Lab Asia Inc. | Sunamp Ltd. | va-Q-tec AG