TOOLS

New database calculates ‘effective’ properties of PCMs

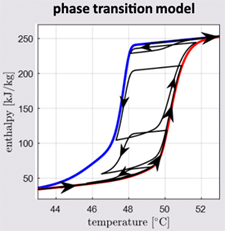

The Austrian Institute of Technology has published a database of solid-liquid phase change materials that generates computer code to estimate their real-world thermal properties.

In a LinkedIn post, the institute described slPCMlib as “the #first #opensource #database which provides computer #code for the calculation of PCM #effective thermal properties in the following programming languages: #Matlab, #Python, #Modelica/ #Dymola, and soon #ANSYS #Fluent.”

In a LinkedIn post, the institute described slPCMlib as “the #first #opensource #database which provides computer #code for the calculation of PCM #effective thermal properties in the following programming languages: #Matlab, #Python, #Modelica/ #Dymola, and soon #ANSYS #Fluent.”

So far, the database lists 153 mostly commercial paraffin-, fatty acid- and hydrated salt-based PCMs from six manufacturers: Axiotherm, Climator, Croda, Knauf, Pluss Advanced Technologies and Rubitherm.

Tilman Barz, senior scientist at AIT’s Center for Energy, led development of the database.

“While there is abundant information on PCM thermal properties available, such as heat capacity, thermal conductivity and density, we found that the data quality and formats are usually very different,” he said. “It often needs some elaborate analysis and data processing to transform and link the data to specific software for thermal simulations which is highly inefficient. So, our motivation was to get rid of these tasks and to spend resources on actual problem solving. Moreover, slPCMlib should also support code exchange between people and computing platforms to push collaborative work on engineering of PCM applications.”

Barz began work on the database in June 2022. A web-based version went online in early 2023. At that point, with the help of colleague Fabrizia Giordano, “we started to structure, to categorize and to systematically grow the database. You can see now that there is not only information on thermophysical data in slPCMlib, we also have meta available, such as information on the manufacturer, measurement methods, preparation of materials, etc. And there is also the possibility to generate code for different programming languages.”

Barz and Giordano plan to continue adding manufacturers and products to the database.

“The database is expanding from month to month, and we are aiming to include as many PCMs as possible, in order to cover different applications,” Giordano said. “We are constantly in contact with manufacturers internationally, as our goal is to provide data for mostly commercially available PCMs. However, we have also started reviewing literature to include new data or for verification of PCM properties already included in slPCMlib.”

Manufacturers have been mostly supportive of the project.

“They have provided us with their PCM datasheets and additional information on measurement procedures and raw data,” Giordano said. “We generally try to establish a direct contact with the companies. However, we also respect the decision of some manufacturing companies, who prefer to not share their data and they limit their contribution to the datasheets available on their website.”

The feedback from researchers has been encouraging. On May 24, Barz and Giordano presented slPCMlib at the Eurotherm Seminar in Lleida, Spain.

“It was largely agreed that this type of database is needed especially in research community, as this could not only save them time in coding of models, but also could give quick overview of available PCMs for an intended application, by comparing the different thermal properties of many commercial PCMs at a glance,” Giordano said. “There was also a certain enthusiasm from the academia when considering the possibility to use slPCMlib for collaborative work and having the possibility to refer to a PCM platform at international level.

“At the moment slPCMlib includes PCMs melting in the temperature range between -61 and 115 °C: Several researchers working in the industrial field encouraged us to expand our database also to high-temperature PCMs, so this will be definitely something on our list for the future.

“Industry also proposed a collaboration to validate our models which of course is of great importance for us, not only to make slPCMlib more and more connected to the industrial world, but also to increase the reliability of our library. Last but not least, several international institutes proposed us to exchange data which were measured at their laboratories. This is also great news for us, as it could enable us to increase the database significantly.”

The slPCMlib project is funded by the European Union Horizon Europe Program under grant agreement No 101096789 (HYSTORE). For more information, contact Tilman Barz.

IN BRIEF

• Phase Change Solutions Inc. is moving its headquarters 25 miles north, from Asheboro to Greensboro, N.C. The PCM manufacturer’s investment in the new location is expected to be more than $3.5 million. A performance-based grant of $75,000 from the state’s One North Carolina Fund will help with the move. “The move to Greensboro allows us to consolidate our existing locations into one,” said Pallavi Madakasira, the company’s vice president for strategic marketing and corporate development. “This will improve our operational efficiencies, and is a better fit with our overall strategy for innovation, business expansion and growth.”

• Va-Q-tec AG, Würzburg, Germany, has signed a partnership agreement with Sartorius AG, Goettingen, Germany, to optimize logistics for shipping temperature-sensitive bulk drug substances. Through the partnership, Sartorius’ new Celsius single-use shippers and va-Q-tec’s va-Q-tainers will be combined.

• Va-Q-tec AG, Würzburg, Germany, has signed a partnership agreement with Sartorius AG, Goettingen, Germany, to optimize logistics for shipping temperature-sensitive bulk drug substances. Through the partnership, Sartorius’ new Celsius single-use shippers and va-Q-tec’s va-Q-tainers will be combined.

• Brenmiller Energy Ltd. has launched its thermal energy storage gigafactory in Dimona, Israel. The new facility will serve as Brenmiller’s primary manufacturing hub. The company said its production lines are expected to reach full capacity by the end of 2023, producing up to 4 GWh of its bGen TES modules annually. The bGen system enables the use of renewable energy and waste heat to heat crushed rocks to very high temperatures. The system stores the heat until it is needed for industrial and power-generation processes.

• Antora Energy‘s thermal battery has been named one of Fast Company’s 2023 World Changing Ideas. The California company’s technology uses wind and solar electricity to heat blocks of solid carbon to temperatures above 1500 degrees C. This heat can then be used in high-temperature industrial processes such as steel-making, at a lower cost than fossil fuels. Brenmiller Energy of Israel also made the Fast Company list.

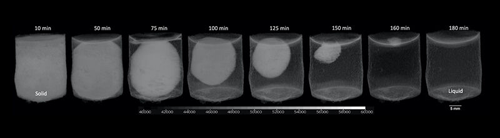

• “Did you ever wonder how an ice cube actually melts?” asks Switzerland’s Lucerne School of Engineering and Architecture in a LinkedIn post. “LuCi [Lucerne CT imaging] is so fast that she can track the melting process of an ice cube in full 3D. Based on these data we can determine the liquid fraction over time, shrinkage, volumetric melting velocities, and many more properties of the melting process.” The LuCi team invites inquiries. Contact Jorge Martinez Garcia, senior research associate, at jorge.martinezgarcia@hslu.ch.

• Also from Lucerne School of Engineering and Architecture via LinkedIn: “Our master’s students Tim Zgraggen and Simon In-Albon have founded the start-up SeasonCell together with three other master’s students from HSLU Hochschule Luzern and ZHAW Zürcher Hochschule für Angewandte Wissenschaften. Their goal is to support the path to a CO2-neutral future with a novel seasonal heat storage system based on phase change materials. The SeasonCell team is in close cooperation with our Center of Excellence for Thermal Energy Storage and we support your work and goals with all our might. We would be very pleased to be able to support the team with a grant from the Luzerner Kantonalbank and are grateful for EVERY vote of the public voting!” You can vote here: landing.lukb.ch/zukunftspreis/seasoncell

• Mirco Schnur, formerly sales agent at va-Q-tec AG, has been promoted to project and implementation manager at the company.

• CIC energiGUNE, Spain, is looking for a postdoctoral researcher in the field of phase change materials for latent heat storage at high temperatures (600-900°C). The research involves a European project that aims to develop new ceramic-PCM composites for waste heat recovery and storage in energy intensive industries.

PATENTS

Compositions containing phase change materials and systems including the same

U.S. patent application 20230130589 (applicant Phase Change Solutions, Greensboro, N.C.):

U.S. patent application 20230130589 (applicant Phase Change Solutions, Greensboro, N.C.):

“In one aspect, compositions are described herein which include a first phase change material (PCM) component comprising an organic PCM, a second PCM component comprising an inorganic PCM, and a crosslinker linking the first PCM component to the second PCM component. In another aspect, a thermal energy storage system is described herein which comprises a container, a heat exchanger disposed within the container, and a composition described herein disposed within the container. The heat exchanger and the composition of such thermal energy storage systems are in thermal contact with one another.”

Bedding or seating product having topper with at least one thermally enhanced foam component

U.S. patent application 20230141576 (applicant L&P Property Management Co., South Gate, Calif.):

“A three-layered topper for a bedding or seating product has a first piece of foam, a second piece of foam and a pocketed spring comfort layer therebetween. The pocketed spring comfort layer has individually pocketed mini coil springs. At least one of the foam pieces may be infused with metallic particles to improve thermal conductivity. Alternatively, at least one of the foam pieces may be infused with microencapsulated phase change materials to improve heat absorption. At least one of the foam pieces may have a coating to further improve thermal conductivity or heat absorption.”

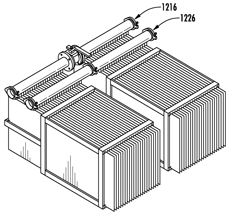

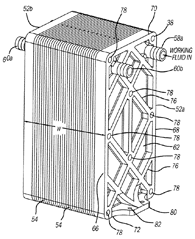

Thermal battery and heat exchanger assembly

U.S. patent application 20230148170 (applicant Emerson Climate Technologies Inc., Sidney, Ohio):

U.S. patent application 20230148170 (applicant Emerson Climate Technologies Inc., Sidney, Ohio):

“A heating and cooling (HVAC) system that includes a compressor; a first heat exchanger; a second heat exchanger; a first expansion valve positioned between the first heat exchanger and the second heat exchanger; a first reversing valve that permits the system to operate in a first mode and a second mode; and a thermal battery including a phase change material therein that is configured to selectively store and release thermal energy received from a working fluid.”

More U.S. patent applications:

Two-phase flow active and passive multilevel data center cooling device (Southeast University, Nanjing, China) | Bedding components including a convoluted foam layer (Dreamwell Ltd., Doraville, Georgia) | Flexible heating device (Calefact Ltd., Hong Kong) | Hybrid energy storage systems (Higher Dimension Materials Inc., St. Paul, Minnesota) | Product transport containers (Product Transport Containers, Charlotte, N.C.)

RESEARCH ROUNDUP

From Journal of Energy Storage:

• Form-stable phase change electrospun nanofibers mat with thermal regulation and biomedical multi-functionalities

• Application of phase change materials for performance enhancement of open-display supermarket refrigerators: Numerical simulation and parametric study

• Microencapsulated phase change material incorporated light transmitting gypsum composite for thermal energy saving in buildings

• Thermal performance and energy saving using phase change materials (PCM) integrated in building walls

• Thermal properties of PEG-based form-stable Phase Change Materials (PCMs) incorporated in mortars for energy efficiency of buildings

From Scientific Reports:

From Applied Thermal Engineering:

From Energy Sources:

• Development of novel phase change materials based on methyl laurate and fatty acids for low-temperature applications

• Energy analysis of a novel butterfly serpentine flow-based PV/T and PV/T heat pump system with phase change material – an experimental comparative study

From International Journal of Technology:

From Journal of Thermal Analysis and Calorimetry:

From Journal of Cleaner Productions:

From Journal of Thermal Science:

From Construction and Building Materials:

• Development of a new lightweight gypsum composite: Effect of mixed treatment of barley straws with hot water and bio-based phase change material on the thermo-mechanical properties

• Preparation and characterization of binary eutectic phase change material laden with thermal conductivity enhancer for cooling steel slag asphalt pavement

• Integration of phase change material and thermal insulation material as a passive strategy for building cooling in the tropics

From Journal of Materials Research:

From Heat Transfer Research:

From International Journal of Heat and Mass Transfer:

• Multi-scale analysis for solidification of phase change materials (PCMs): Experiments and modeling

From International Communications in Heat and Mass Transfer:

• Experimental results of embedded phase change material capsules for increasing the performance of a wrapped heat pump water heater

• Experimental investigation of a thermal response behavior of d-mannitol as phase change material

From Fire:

From Materials Today: Proceedings:

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,780 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,780 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Russ Jones, visiting scholar at the Center for Energy Research at the University of California, San Diego; Robert Morton, president at Stasis Energy Group, Pomona, Calif.; Miriam Rico, marketing analyst at Phase Change Solutions Inc., Asheboro, N.C.; and Laura Fernández González, business development representative, Croda International Plc., Barcelona, Spain.

A new post from group member Harald Mehling: “I am happy that ‘Analysis of trends in phase change enthalpy, entropy and temperature for alkanes, alcohols and fatty acids’ is now published, a paper that I wrote together with Mary Anne White. It is OpenAccess, and you find it via ResearchGate or directly at the publisher at https://lnkd.in/ezYy2bEf.”

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

Axiotherm GmbH | Croda International Plc. | ISU Chemical Co. Ltd. | RuhrTech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | S.Lab Asia Inc. | Sunamp Ltd. | va-Q-tec AG