NEW PRODUCTS

Va-Q-tec introduces alternative to dry ice

Va-Q-tec AG, Würzburg, Germany, has developed a new phase change material that enables transport of cell and gene therapy cultures at -70° C without the use of dry ice.

The new PCM, –67G, is a eutectic salt hydrate with a melting point of -67 °C. The PCM is contained in HDPE panels that fit in the company’s va-Q-proof shippers. The product is now commercially available and in use worldwide.

The new PCM, –67G, is a eutectic salt hydrate with a melting point of -67 °C. The PCM is contained in HDPE panels that fit in the company’s va-Q-proof shippers. The product is now commercially available and in use worldwide.

Dry ice is the solid form of carbon dioxide, commonly used for temporary refrigeration of temperature-sensitive payloads. As it evaporates during transport and storage, it releases carbon dioxide, which can displace oxygen quickly in enclosed spaces, making it subject to special handling requirements and air freight restrictions.

Va-Q-tec says its new PCM “is not a hazardous material in accordance with IATA rules, it is also neither toxic nor flammable and can be reused hundreds of times without any loss of performance.”

“These characteristics make it extremely sustainable compared to dry ice,” the company says. “They also make it easier to plan logistics: dry ice is often not available in sufficient quantity at short notice. Conversely, shippers can have the cooled PCM available anytime.

“Therefore, biopharmaceutical companies can minimize the use of dry ice to situations where its use is unavoidable, such as for long-distance intercontinental transport. In some scenarios within the clinical-pharmaceutical sector, maintaining a temperature of -70 C for extended periods during transport is necessary. When used in va-Q-proof packaging, the new -67G PCM is qualified for up to 72 hours below -60° C.”

HeatVentors adds smaller HeatTank to thermal battery lineup

Hungarian startup HeatVentors will launch the newest (and smallest) member of its HeatTank thermal battery lineup in December.

HeatVentors’ thermal batteries use phase change material to store renewable energy and off-peak grid energy to provide hot water, heating and cooling on demand. An intelligent controller connected to the heating and cooling circuits optimizes energy use by monitoring the charge/discharge process, indoor/outdoor temperatures, user preferences and the availability of cheaper energy.

HeatVentors’ thermal batteries use phase change material to store renewable energy and off-peak grid energy to provide hot water, heating and cooling on demand. An intelligent controller connected to the heating and cooling circuits optimizes energy use by monitoring the charge/discharge process, indoor/outdoor temperatures, user preferences and the availability of cheaper energy.

The new HeatTank 10, which retails for 6,000 euros, is designed for use in homes and apartments. The company says it can reduce energy costs by 20% to 50% and cut CO2 emissions by 30% to 50%.

Christoph Thomas, HeatVentors’ country manager for Germany, Austria and Switzerland, answered questions about the company and its new product by e-mail.

Q: Who are HeatVentors’ key customers?

A: “Companies with a need to save energy quickly and make their existing infrastructure more efficient. This includes shopping and data centers; hotels as well as district heating and cooling networks.”

Q: Can you provide technical details on the PCM?

A: “We cover in our intelligent thermal battery temperatures from -30C to 120C; each battery is designed to work to the customer’s specific cooling and heating needs.”

Q: In what material is it contained?

A: “The HeatTank 10, 20 and 50 are double-walled stainless steel batteries with insulation in between.”

Q: What is the source of the PCM?

A: “We use a variety of sources, mainly from external suppliers. We work with them to develop improvements and new materials.”

Q: What will be the biggest challenge for HeatVentors in 2024 and beyond?

A: “The main challenge for any start-up is to scale; meaning driving sales, optimizing supply / production and addressing new markets while staying agile, innovative and financially sound.”

IN BRIEF

• Registration is open for the 11th Swiss Symposium Thermal Energy Storage, to be held Jan. 26, 2024, at the Lucerne School of Engineering and Architecture. The theme: “Bridging the gaps: How can we support the energy transition today and in the future?” Presenters include Gerald Englmair, assistant professor at the Technical University of Denmark, who will share insights on “Cool-Data – PCM cold storage for server room cooling.”

• Jake Adamson, a graduate engineer at the FairHeat energy consultancy in London, sizes up the benefits of thermal storage in heat networks in a CIBSE Journal article summarizing his research into the potential for reducing electric boiler capacity. He writes: “In the past, we have ventured into predictive hourly models to select heat pump and thermal storage sizes. However, the purpose of the research was to use operational heat network data to assess how the size of thermal storage would have impacted the required boiler capacity during the peak months: typically November to March. The findings showed that by increasing and oversizing the thermal storage volume, it is possible that marginal reductions in electric boiler capacity, in the region of 15-30%, could start to be considered. This could result in capital cost savings for developers – but it also poses a risk that must be mitigated.”

• Jake Adamson, a graduate engineer at the FairHeat energy consultancy in London, sizes up the benefits of thermal storage in heat networks in a CIBSE Journal article summarizing his research into the potential for reducing electric boiler capacity. He writes: “In the past, we have ventured into predictive hourly models to select heat pump and thermal storage sizes. However, the purpose of the research was to use operational heat network data to assess how the size of thermal storage would have impacted the required boiler capacity during the peak months: typically November to March. The findings showed that by increasing and oversizing the thermal storage volume, it is possible that marginal reductions in electric boiler capacity, in the region of 15-30%, could start to be considered. This could result in capital cost savings for developers – but it also poses a risk that must be mitigated.”

• Sunamp Ltd. writes on LinkedIn: “We are thrilled that Sunamp’s heat batteries have won the ‘Product – Scotland’ award at the prestigious VIBES Awards. Our commitment to building phase change material heat battery for a sustainable future is recognised, and we couldn’t be prouder.” The VIBES Scottish Environment Business Awards recognise organisations that have demonstrated significant business benefits from good environmental practices.

• Also from Sunamp on LinkedIn: “A winning streak – we’re thrilled to share that Sunamp has won The Spectator‘s Economic Innovator of the Year award (in partnership with Investec) in the ‘Scale Up – International’ category, Scotland & Northern Ireland region. This prestigious award recognises the shining talents of British entrepreneurship, and it highlights our journey from local visionaries to global innovators in thermal energy storage technology.”

• UK-based Tower Cold Chain unveiled its new Evolution 1600 Tower Universal Pallet at CPHI Barcelona 2023. The shipping system is designed for pharmaceutical products that need to be kept between -60° C to +20°C for 120 hours without the need of electricity or manual intervention during transit. The pallet features double doors and an “ultra lightweight” design.

• Malta Inc., a Massachusetts company that spun out of Google’s moonshot factory in 2018 to work on long-duration energy storage, announced that its German subsidiary has been awarded a grant to support a 9-million-euro effort to accelerate the German energy transition. Malta Hochtemperatur Wärmepumpen Stromspeicher GmbH, German Aerospace Center, Alfa Laval and Siemens Energy were awarded funding by Germany’s Federal Ministry for Economic Affairs and Climate Protection to support the country’s efforts to achieve Paris Agreement climate targets and to be climate-neutral by 2045.

• B Medical Systems of Luxembourg is the newest member of the RAL Quality Association PCM. The 35-year-old company manufactures and distributes medical refrigeration devices.

PATENTS

Fast charging batteries at low temperatures with battery pack preheating

U.S. patent application 20230361366 (applicant Beam Global, San Diego, California):

U.S. patent application 20230361366 (applicant Beam Global, San Diego, California):

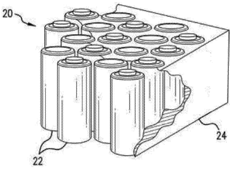

“A method and apparatus for charging a battery pack including a plurality of electrochemical cells distributed within a thermal management composite matrix, including a phase change material. The method operates upon determining that a battery pack temperature and/or voltage measurement is below a predetermined minimum threshold. The pack temperature and/or the voltage measurement is raised to the predetermined minimum threshold, such as by applying a low current rate, and then the charging rate is increased upon reaching the predetermined minimum threshold. The increased charging rate is further selected based upon a thermal state of charge of the thermal management composite matrix.”

Encapsulation of thermal energy storage media

U.S. patent application 20230365849 (applicant University of South Florida, Tampa, Florida):

“In one embodiment, a phase change material is encapsulated by forming a phase change material pellet, coating the pellet with flexible material, heating the coated pellet to melt the phase change material, wherein the phase change materials expands and air within the pellet diffuses out through the flexible material, and cooling the coated pellet to solidify the phase change material.”

More U.S. patent applications:

Implantable medical device for the delivery of an antipsychotic (Celanese EVA Performance Polymers LLC, Irving, Texas) | Rapid mercury-free photochemical microencapsulation/nanoencapsulation at ambient conditions (University of Doha for Science and Technology, Doha, Qatar) | Temperature control plate for cold-chain transportation and measurement method for temperature control plate (Thero New Material Technology Co. Ltd., Shenzhen, China) | Phase change heat exchanger (Sungro Power Supply Co. Ltd., Hefei, China) | Phase change materials to address reversion problem in heavy oils (Baker Hughes Oilfield Operations LLC, Houston, Texas)

RESEARCH ROUNDUP

From Journal of Energy Storage:

• Experimental evaluation of different macro-encapsulation designs for PCM storages for cooling applications

• Phase change materials for storing heat extracted from heat pump condensers

• Analyzing long-term reliability and potential of organic eutectic Phase Change Material as thermal batteries

• Bio-based phase change materials for thermal energy storage and release: A review

• Innovation and progress in the incorporation of phase change materials into radiant floor systems

From AIP Conference Proceedings:

• Experimental study of calcium chloride as phase change material for fish cold storage

• Thermal analysis of firefighter jacket embedded with micro encapsulated phase changing material

From Buildings:

• Study of Pavement Performance and Temperature Regulation Capacity of Asphalt Binders Modified with Dual-Phase-Change Materials

• Study on the Performance of Phase-Change Self-Regulating Permeable Asphalt Pavement

From Surgeries:

From Applied Energy:

From International Journal of Thermophysics:

• Di-Alkyl Adipates as New Phase Change Material for Low Temperature Energy Storage

• Thermal Performances of Myristic Acid/Bentonite/Graphene Composite Phase Change Materials

From Physical Chemistry Chemical Physics:

From Journal of Thermal Science:

From Journal of Building Engineering:

• Effect of phase change material (PCM) on thermal inertia of walls in lightweight buildings

From Fibers:

From Energy and Built Environment:

From BuildSys ’23:

• Utilizing Phase Change Material Integration for Passive Cooling in Direct Heat Gain Walls

From Proceedings of the Institute of Mechanical Engineers:

• Energy and exergy analysis of latent heat storage with heat pipe encased in phase change material

From Renewable Energy:

From Renewable and Sustainable Energy Reviews:

• Phase change material window for dynamic energy flow regulation: Review

• Phase change material (PCM) candidates for latent heat thermal energy storage (LHTES) in concentrated solar power (CSP) based thermal applications – A review

• Personal cooling garments and phase change materials: A review

From Applied Thermal Engineering:

• Experimental analysis of a power-to-heat storage with high-temperature phase change materials to increase flexibility and sector coupling

• A phase change material (PCM) based novel retrofitting approach in the air conditioning system to reduce building energy demand

From Forests:

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,800 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,800 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Yuwen Zhang, Curators’ Distinguished Professor and Huber and Helen Croft Chair in Engineering at the University of Missouri-Columbia; Koorosh Khosravi, Ph.D. student in mechanical engineering at Rensselaer Polytechnic Institute, Troy, New York; Xuehui Wang, assistant professor at University College Dublin, Ireland; Joris de Luij, chief commercial officer PCM at PLUSS Advanced Technologies, s-Hertogenbosch, Netherlands; Pravin Omprakash Sharm, Ph.D. research scholar in mechanical-mechatronics engineering at LNM Institute of Information Technology, Jaipur, India; Róbert Ágoston, senior energy efficiency consultant at Press Air Kft, Budapest, Hungary; Sebastian Sonnick, founder at MELT, Mutterstadt, Germany; Ulises Ulloa Gaytan, engineering services adviser at RAAD Ingenieros, Monterrey, Mexico; and Anand K. Joshi, doctoral researcher at Presidency University Bangalore, Bangalore, India.

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

Axiotherm GmbH | B Medical Systems | Croda International Plc. | ISU Chemical Co. Ltd. | RuhrTech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | S.Lab Asia Inc. | Sunamp Ltd. | va-Q-tec AG