AGRICULTURE

Nonprofit rolls out an educational greenhouse on wheels

A portable greenhouse now making the rounds in Cochrane, Alberta, shows how passive solar technology combined with phase change material can extend the region’s short growing season more efficiently than traditional greenhouses.

Funded by a Canada Healthy Communities Initiative grant, Cultivate Cochrane’s Passive Solar Roller is helping the nonprofit community group spread its vision for sustainable agriculture and locally sourced food.

Conventional “glass” greenhouses can overheat on sunny days and lose heat quickly during Alberta’s bone-chilling winter nights. Passive solar greenhouses like Cultivate Cochrane’s moderate those temperature swings, using PCMs to absorb excess heat during the day and release it at night.

The 144-square-foot Passive Solar Roller is built on a flatbed trailer. The steep south-facing roof features polycarbonate panels that provide a balance between insulation value and light transmission. The walls and floor are well insulated to hold warmth in winter. PCM-filled Templok Tiles made by Insolcorp of North Carolina line the back wall and parts of the side walls. A small photovoltaic panel on the roof powers a fan that drives hot air into the soil beds.

Frankie-Lou Nelligan, Cultivate Cochrane’s executive director, explains more about the project:

Q: How did your team first hear of phase change materials?

A: “When our board members were first researching the possibility of building a greenhouse to assist with growing food in our challenging agricultural region, they did a great deal of reading and research about techniques and design features that could help extend our terribly short growing season here in Alberta. The idea of phase change materials was first noticed in a book called ‘Year Round Solar Greenhouse’ by Lindsey Schiller.”

Q: What can you tell me about the PCM panels?

A: “The PCM has a melting point of 77F / 25C. We bought three cases of the Templok Tile, enough to cover the back wall of the greenhouse and some portion of the side walls. The tile cost $943 Canadian, including tariffs.”

Q: Do you have any metrics on how the PCM is performing since its debut in May 2022? If no hard numbers are available, can you describe the effect in lay terms, based on your experience?

A: “Over the 17 months that the Solar Roller has been in use, we have found that the phase change material has provided an average of 2-4 degrees Celsius protection from colder temps. This is actually quite significant when you consider how much that has allowed us to extend our growing season. Here in the Cochrane region, we can often get a few sudden hard frosts as early as the last week of August. Normally this would kill off the more tender plants like tomatoes. It can be so frustrating as these frosts can be followed by several weeks of great weather. The only thing that is consistent about the growing conditions in our region is that they are so inconsistent!

“Working in conjunction with our climate battery (that circulates the air through the thermal mass of our large raised beds), the few degrees of frost protection provided by the PCM meant that we were able to grow tomatoes into the beginning of November. We were able to start growing new plants again in March. We are hoping to push the season a bit further this year. Basically with the various design features we incorporated into the Solar Roller, including PCM, we were able to grow veggies for eight months, a very significant extension.”

Q: Part of Cultivate Cochrane’s vision is to build a permanent greenhouse that will include features of the mobile greenhouse. How big will that greenhouse be, will it include PCM and when will it likely be completed?

A: “We are hoping to build a larger permanent community greenhouse within a few years, provided we can garner enough support through funding, land and labor. We are hoping this community greenhouse hub would provide inter-generational programming and education to support food sovereignty and security in our region. Ideally, this would be quite a large facility (1,500-2,000 square feet of greenhouse space).

“We are learning quite a bit about passive and active greenhouse design through our work with the Solar Roller. One thing that is very apparent is that applying several different design elements at the same time works best. Creating a great deal of thermal mass within the little greenhouse through large raised beds, a big water tank, the use of good insulation paired with PCM, orientation for best sunlight capture have all worked very well together. With the permanent nature of the larger greenhouse, we would likely use these design features again and also tap into geothermal energy as well to hopefully create a true four-season greenhouse.

“One thing that we have found particularly effective about the PCM is that it doesn’t take up a whole lot of space and is actually much lighter than other ways of building thermal mass. As the Solar Roller is quite small and also portable, the PCM has been a great space saver and makes it easier to tow.”

IN BRIEF

• The EU’s iClimaBuilt Project has announced an open call for 10 projects that can “bridge the knowledge gaps in the building sector and the Nearly Zero Energy Buildings #nZEBs concept.” The goal is to promote the scale-up of novel materials and technologies for building envelopes. The winning proposals will receive technical support from iClimaBuilt and up to 150,000 euros in funding. Eligible entities include small and medium-size enterprises, small consortia and R&D organizations established within the EU and EEA. Applications are due by Dec. 30, 2023.

• Westinghouse Electric Co. has secured a $50 million U.S. government grant for a 1.2GWh pumped thermal project it is developing in Alaska. The company says it will be the largest energy storage facility in the United States. It is one of 15 projects getting a share of $325 million awarded by the Department of Energy as part of President Biden’s “Investing in America” agenda.

• Camila Barreneche, an associate professor at the University of Barcelona, has been working with Rocco Lupoi of Trinity College Dublin to develop “a radically new material (ThermoDust) with outstanding heat transfer performance.” The project is funded by the European Union and the European Innovation Council.

• A team of undergraduate students at Montreal’s Concordia University has won the school’s Capstone Sustainable Development Goals Impact Award. Their project: “Novel Phase Change Materials (PCM) Chilled Beam HVAC Test Stand.” The new award honors capstone projects that align with the United Nations’ 17 sustainable development goals.

• PLUSS Advanced Technologies has launched two new temperature-controlled shippers for the pharmaceutical industry. The company, based in Gurugram, India, says the Celsure XL pallet shipper and Celsure VIP multi-use parcel shipper “are designed to guarantee temperature integrity across geographies and seasons.”

JOBS

• The Thermal Energy Storage Research Group at Oak Ridge National Laboratory in Tennessee is looking to hire a full-time R&D associate “responsible for conducting, coordinating, and reporting complex research assignments related to energy conversion systems,” including phase change material characterization and synthesis; integration of thermal energy storage with HVAC equipment; and heat exchanger design.

• The University of Bologna is looking to hire a researcher in the field of heat transfer and HVAC systems. The primary objective is the development of procedures to enhance the performance of HVAC systems based on heat pumps and equipped with latent heat storage tanks equipped with phase change materials.

PATENTS

U.S. patent application 20230295918 (applicant UT-Battelle LLC, Oak Ridge, Tennessee):

U.S. patent application 20230295918 (applicant UT-Battelle LLC, Oak Ridge, Tennessee):

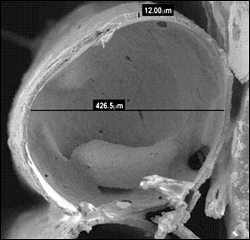

“A method of encapsulating a phase change material includes providing a co-axial ejector including first and second coaxially-disposed outlets, with the first outlet being inside of and surrounded by the second outlet. A core composition including a phase change material is fed to the first outlet. A coating composition is fed to the second outlet. The core composition and the coating composition are simultaneously ejected from the ejector onto a collector. The core composition is surrounded by the coating composition and together ejected onto the collector to form an encapsulated core-shell phase change material fiber. No voltage is applied to the ejector during ejection, and the method does not include electrospinning. The core-shell fiber has a phase change material core surrounded by a polymer shell and a diameter in the range of 10-10,000 μm. The core constitutes from 30% to 97% by volume of the core-shell fiber.”

Supercooling cancellation device

U.S. patent application 20230250749 (applicant Panasonic Holdings Corp., Osaka, Japan):

“A supercooling release device according to one aspect of the present disclosure releases a supercooled state of a heat storage material. The supercooling release device includes a first member and a second member capable of being brought into contact with each other. The first member and the second member each include a metal. While a load is continuously applied to at least one of the first member and the second member to bring at least a portion of a surface of the first member and at least a portion of a surface of the second member into close contact with each other, the supercooled state is maintained. When the supercooled state is to be released, the supercooling release device reduces the above load.”

U.S. patent application 20230286861 (applicant Compass Minerals America Inc., Overland Park, Kansas):

U.S. patent application 20230286861 (applicant Compass Minerals America Inc., Overland Park, Kansas):

“The present disclosure is directed to phase change material compositions, low temperature applications for phase change materials, snow-melt applications for phase change materials, and deicing applications for phase change materials. In some embodiments, phase change materials comprise lightweight aggregates. In some embodiments, the low temperature and deicing applications include concrete applications.”

More U.S. patent applications:

Heat exchange system for freezing, transferring, storing and utilizing phase change material (Active Energy Systems, Knoxville, Tennessee) | Systems with multi-circuite, phase change composite heat exchangers (Alliance for Sustainable Energy LLC , Golden, Colorado) | Thermally insulated transport container (Gobi Technologies Inc., Kirkland, Washington) | Recyclable, thermally insulated shipping container with packed, loose-fill organic insulation and PCM bladder insert (Packaging Technology Group LLC, Fall River, Massachusetts)

RESEARCH ROUNDUP

From Journal of Energy Storage:

• A novel carbon reducing natural composite phase change material for effective energy storage

• A perspective on Phase Change Material encapsulation: Guidance for encapsulation design methodology from low to high-temperature thermal energy storage applications

• Compatibility of container materials with peritectic phase change material for high-temperature thermal energy storage

From ACS Applied Energy Materials:

From BioResources:

From Science and Technology for the Built Environment:

From Case Studies in Thermal Engineering:

From Renewable and Sustainable Energy Reviews:

• Review of bio-based phase change materials as passive thermal storage in buildings

• Recent advances of low-temperature cascade phase change energy storage technology: A state-of-the-art review

• Potential of latent thermal energy storage for performance improvement in small-scale refrigeration units: A review

From Applied Thermal Engineering:

• Performance and life cycle assessment of pillow plate heat exchanger utilizing microencapsulated phase change material slurry

• Microencapsulation of eutectic phase change materials for temperature management of the satellite electronic board

• Thermal and energy performance evaluation of a dry floor heating system based on hybrid heat storage aggregates for field application

From Construction and Building Materials:

• Novel gypsum based plasters with phase change material impregnated lightweight aggregates for energy efficient retrofitting

• Validated simulation of thermal performance of phase change material infused recycled brick aggregate in 3D printed concrete

From World Electric Vehicle Journal:

From Journal of Coatings Technology and Research:

• A review on microencapsulated phase change materials in building materials

From Journal of Materials in Civil Engineering:

From AIP Conference Proceedings:

• Design of mobile cold storage system using phase change material for vaccines

From Environmental Science and Pollution Research:

From Trends in Food Science & Technology:

From HAL Open Science:

• Experimental study on starch/tetradecane phase change material for cold energy storage

From Journal of the Brazilian Society of Mechanical Sciences and Engineering:

• Evaluating energy-saving potential in micro-cold storage units integrated with phase change material

From Journal of Composites Science:

From Materials Today: Proceedings:

• Phase change material on the integration of PCM in the building envelope

From Nature Communications:

NETWORKING

Connect with PCM experts and industry leaders on LinkedIn

More than 1,800 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

More than 1,800 people have joined a LinkedIn group devoted to the discussion of phase change material and thermal energy storage. You are invited to join the Phase Change Matters group and connect with PCM and TES experts from around the world.

This month we welcome Andrea Rubio Aguinaga, Ph.D. student at the University of Navarra, Pamplona, Spain; Christine Boucher, energy and climate action committee board member, Brewster, Massachusetts; Drew Maggio, building efficiency sales engineer at Highmark, New York, N.Y.; and Isra Benyounes, materials supervisor at Elbayrak Construction, Algiers, Algeria.

NEWS TIPS

Does your company, agency or university have a job opening, new research, new product or other news you’d like to share? I would love to hear from you. Please contact newsletter editor Ben Welter at benedict.welter@gmail.com.

A WORD FROM OUR SPONSOR

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

This newsletter is made possible through the generous support of the RAL Quality Association PCM and the members listed below. To learn more about the association, including membership benefits, please contact Stefan Thomann, executive director, at pcm@kellencompany.com.

Axiotherm GmbH | Croda International Plc. | ISU Chemical Co. Ltd. | RuhrTech | Microtek Laboratories | PCM Technology | PLUSS Advanced Technologies | PureTemp LLC | Rubitherm Technologies GmbH | Sasol Germany GmbH | S.Lab Asia Inc. | Sunamp Ltd. | va-Q-tec AG